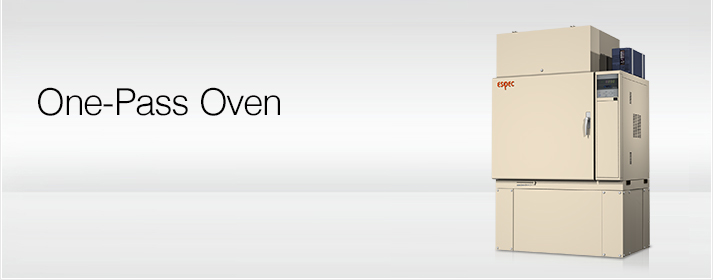

Prevents an explosion in heat treatment and drying materials which include volatile solvent.

Some synthetic resin and coating materials include volatile solvent. The heat treatment, drying and temperature characteristics test of these materials have possibility of explosion with using the conventional chamber because it employed air circulating method and the concentration of the flammable gases generated became high. ESPEC all-exhaust temperature chamber controls gas concentration increase and prevents an explosion by all-exhaust method (non-circulating method).

Features

- High-safety all-exhaust method

- The air in the chamber is exhausted to the outside. The chamber is filled with fresh air heated by heater.

- Advanced temperature control

- The temperature fluctuation ±0.5°C (100°C) and ±1.0°C (200°C) can be obtained thanks to preheating heater.

- Adopted uninterruptible power supply

- An uninterruptible power supply is adopted to prevent circulating mechanism from stopping by power failure. Additional safety is pursued by using such optional equipment as gas detector.

- Equipped with explosion vent (safety door)

- Controlling gas concentration low can not prevent explosion totally. Some gases may explode even if their concentrations are low. In those cases, the explosion vent will protect you.

- Explosive pressure is released from the above when explosion occurs in the chamber.

- Contamination control of specimens

- The specimen is protected from contaminations caused by substances generated when specimen are heated.

Construction

- Construction

-

- Air flows like arrows in the right figure.

- The air is heated in the suction box and introduced to chamber.

- The air in the chamber is not circulated and exhausted to outside.

- [Conventional method]

- (In case of SPH-201S and 301S)

- Specifications

-

Model SPH-202 SPH-302 SPH-402 System non-circulating method Power supply 200/220/230/240V AC 1φ 50/60Hz 200/220V AC 3φ 3W 50/60Hz、380V AC 3φ 4W 50Hz Performance Temperature range (ambient temp.+40°C) to +200°C Temperature fluctuation ±0.5°C(+100°C)

±1.0°C(+200°C)Temperature uniformity ±1.5°C(+100°C)

±3.0°C(+200°C)±3.0°C(+100°C)

±5.0°C(+200°C)±2.0°C(+100°C)

±4.0°C(+200°C)Temperature heat-up and pull-down rates* Within 40 min. from ambient temp. to +200°C Within 60 min. from ambient temp. to +200°C Within 80 min. from ambient temp. to +200°C Exhaust volume About 70m³/h About 80m³/h About 480m³/h Capacity 216L 512L 1000L Dimensions Inner dimensions W600 × H600 × D600mm W800 × H800 × D800mm W1000 × H1000 × D1000mm Outer dimensions W1190 × H1910 × D785mm W1500 × H2300 × D1065mm W1930 × H1800 × D1925mm Weight 230kg 340kg 600kg Instrumentation Setting and indication ranges Temperature: 0 to +210°C

Time: 0 to 99 hrs 59 min, 100 to 999 hrs

(1 hour unit for more than 100 hrs)Setting and indication resolution Temperature:1°C

Time:1 min.Program function Programmable of 2 steps (2-step fixed) * The model name may be changed.

Recommended products for customers viewing this product