Advanced Safety Tester

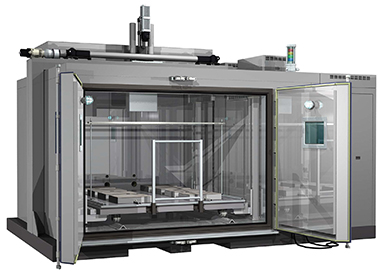

Overview of Equipment

Lithium-ion secondary batteries are adopted wider applications in everything from consumer use to storage and automobiles, and there is greater interest not only in advancing performance testing but also in safety testing.

ESPEC designed the Advanced Safety Tester to perform multiple safety tests under precise temperature environments.

Please scroll horizontally to look at table below.

| Category | Item | Specifications (example) |

|---|---|---|

| Applicable battery | Small capacity cells to laptop battery packs | |

| Test chamber | Temperature range | -40 to 100°C |

| Temperature fluctuation | ±0.3°C | |

| Safety devices |

|

|

| Measurement control unit | System | Test chamber, nail penetration, crushing, external short circuit integrated system |

| Monitored items | (Nail penetration, crushing) load, transfer distance, velocity, battery voltage, battery temperature (External short circuit) battery voltage, battery temperature |

|

| Data output | Monitored items can be saved to a CSV file | |

| Crushing/nail penetration unit | Size of mountable battery | W245 × D215 × H180 mm |

| Load range | 0.4 to 20kN | |

| Velocity | 0.1 to 50mm/sec. | |

| Stroke | 2 to 200mm | |

| External short circuit unit | Short circuit current | 500A |

| Circuit resistance | Resistance switching inside unit (1) 5 mΩ or less (resistance short) (2) 10 to 30 mΩ (3) 80 to 100 mΩ |

|

- * Please contact us for supported test standards and specifications.

- Case studies of large safety testers for automotive secondary battery packs

-

* The specifications, appearance, and other contents herein are subject to change without notice due to continuous product development and improvement. Thank you for your understanding.

-

Large nail penetration and crushing tester

This system is equipped with various safety functions and an electronic elevator stage that can support up to 500 kg and a 2m × 2m size.

-

Large external short circuit tester

The world's first large tester that supports a maximum voltage of 500V and a maximum current of 24,000A.

-

Features

- One unit with four functions. Introducing an all-in-one safety tester.

- The function elements of the safety tester are in separate modules, enabling flexible system construction and expansion.

- The combination of each unit enables support of batteries from small cells to large packs.

- Constructed with an integrated system using a measurement control unit. This system provides central management of testing operations and minimizes complex operations for performing tests.

- One-stop service provides enhanced product and service quality as well as speed.

- Example of system configuration

-