Industrial Ovens Temperature Chamber Series

Overview of Equipment

Worldwide applications

ESPEC's Temperature Chambers are suitable for a broad range of applications from high-temperature testing, to heat treatment or drying for production lines.

Several volumes are available in horizontal (PH series) or vertical (PV series) models.

- High performance chamber

- A temperature-indication controller with an advanced PID operation, and an originally developed chamber configuration provide unmatched oven performance. Temperature uniformity, temperature constancy, temperature heat-up rate, and temperature recovery time are performed with the upmost reliability.

- Wide model selection (PH series)

- We provide a total of 16 ovens with combination of temperature range, capacity, and instrumentation.

- A space-saving upright chamber (PV series)

- Components are incorporated into the top portion of the vertical chamber, reducing installation space by 20 to 60% (comparison with conventional model). Increases productivity on the production line, and saves laboratory space.

Specifications

Please scroll horizontally to look at table below.

| Model | Temperature & range | Inside/Outside dimensions(mm) |

|---|---|---|

| PV-212 (PVH-212) |

(Ambient temp. +20)℃ to +200℃ ((Ambient temp. +20)℃ to +300℃) |

W600×H600×D600 / W770×H1200×D925 |

| PV-222 (PVH-222) |

W600×H900×D600 / W770×H1500×D925 |

|

| PV-232 (PVH-232) |

W600×H1200×D600 / W770×H1800×D925 |

|

| PV-332 (PVH-332) |

W800×H1200×D800 / W1030×H1800×D1145 |

|

| PH-102 (PHH-102) |

(Ambient temp. +20)℃ to +200℃ ((Ambient temp. +20)℃ to +300℃) |

W450×H450×D450 / W1040×H820×D635 |

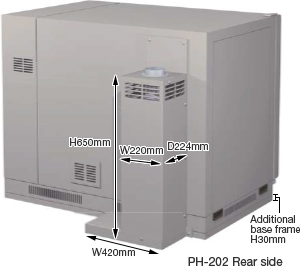

| PH-202 (PHH-202) |

W600×H600×D600 / W1190×H970×D785 |

|

| PH-302 (PHH-302) |

W800×H800×D800 / W1500×H1210×D1065 |

|

| PH-402 (PHH-402) |

W1000×H1000×D1000 / W1730×H1480×D1275 |

- * Specify M-instrumentation for temperature programs with three or more steps.

Features

Two types of program instrumentation to suit different applications.

Standard Instrumentation and M-Instrumentation.

- User-friendly Standard Instrumentation

- Standard Instrumentation features programmed operation with operational settings such as constant mode and automatic start/stop. Suitable for heat treatment, drying, and similar production-line applications.

- M-Instrumentation features programs with up to 20 steps

- Suitable for a range of applications from temperature-characteristics testing to heat treatment and drying. Programmed operation now allows storing ten patterns, each up to twenty steps. Provides a wide range of functions, including temperature ramp settings and a maximum of 999 repeat cycles.

- Easy setup with on-screen display

- Employs interactive settings for ease of use. Text can be displayed and entered in Japanese or English alphanumeric characters.

- Four optional functions

- Four optional functions, namely, air flow adjuster, automatic damper, integrating hour meter, and calendar timer can be included in the instrumentation. These functions can be set by using main panel instrumentation keys.

- Interface (Option)

- Interface for device communication can be selected between RS-485, GPIB and RS-232C.

- Energy Saver Duct (PH series)

- Energy saving approximately 20% by heat recycling from exhaust through the duct to maintain temperature while damper opens.

Environmental

Test Chambers

- Temperature

(& Humidity) Chambers /

Rapid-Rate Thermal Cycle Chambers- Platinous J Series Temperature

(& Humidity) Chamber - Environmental Stress Chamber

AR series - Rapid-Rate Thermal Cycle Chamber

- Bench-Top Type Temperature

(& Humidity) Chamber - Constant Climate Cabinet

- Compact Ultra Low Temperature Chamber

- Stability Test Chamber (CSH)

- Stability Test Chamber (CWH)

- Walk-In Chamber E Series / High-power Series

- Highly Accelerated Stress Test System (HAST Chamber)

- Temperature

(& Humidity) Chamber FD Series - High-Rate Thermal Cycle Chamber

- VOC Emission Test Chamber

- Altitude Temperature

Chamber - Altitude Temperature

(& Humidity) Chamber - Large Highly Accelerated Stress Test System

(HAST Chamber)

- Platinous J Series Temperature

- Thermal Shock Chambers

- Air to Air Thermal Shock Chambers

Fixed test area type /

Elevator type - Thermal Shock Chamber 300°C Specification

- Large Capacity Thermal Shock Chamber TSA-603EL-W

(600L) - Large Capacity Thermal Shock Chamber

- Liquid to Liquid Thermal Shock Chamber

- Large Capacity Liquid to Liquid Thermal Shock Chamber

- Air to Air Thermal Shock Chamber with Humidity

- Highly Accelerated Air to Air Thermal Shock Chamber (HAATS)

- Air to Air Thermal Shock Chambers

- Temperature Chambers

- Industrial Ovens

Temperature Chamber

Series - Industrial Ovens

Ultra-High Temperature Chamber - Industrial Ovens

Temperature Chamber

with Explosion Vent - Industrial Ovens Temperature Chamber with Rotating Specimen Rack

- Industrial Ovens Anaerobic Temerature Chamber

- Industrial Ovens Large Volume Temperature Chamber

- Desk-top Type High-Temp. Chambers

- Convection Oven

- Industrial Ovens High Performance Clean Oven

- Vacuum Oven

- Slide Tray Oven

- Large Clean Oven

- One-Pass Oven

- Anaerobic Oven

(Less than 100ppm)

- Industrial Ovens

- Network Products

- Example Custom Orders

- Combined Temperature & Humidity Chamber

- Weather Simulation Chamber

- Vertical/Horizontal Vibration Combined Environmental Test System

- Multi-axis Vibration Combined Standard Environmental

Test System - Large Highly Accelerated Stress Test System

(HAST Chamber) - Anaerobic Clean Oven

(SCO Series) - Temperature (& Humidity) Chamber with Large, Double-sided Viewing Window