Industrial Ovens Temperature Chamber with Explosion Vent

Overview of Equipment

Heat-treatment process achieved with safety

This industrial oven is suitable for heat-treatment or drying process of synthetic resins or volatile solvent. Safety features such as the explosion vent or the door lock system (single-action lever) allows operation in total safety.

Specifications

Please scroll horizontally to look at table below.

| Model | Temperature range | Inside/Outside dimensions(mm) |

|---|---|---|

| SPH-102 (SPHH-102) |

(Ambient temp. +20)℃ to +200℃ ((Ambient temp. +20)℃ to +300℃) |

W450×H450×D450 / W1040×H1260×D635 |

| SPH-202 (SPHH-202) |

W600×H600×D600 / W1190×H1370×D785 |

|

| SPH-302 (SPHH-302) |

W800×H800×D800 / W1500×H1715×D1065 |

|

| SPH-402 (SPHH-402) |

W1000×H1000×D1000 / W1730×H1800×D1775 |

Features

- Temperature chamber with Explosion Vent

- This temperature chamber is suitable for drying and heat-treatment of flammable synthetic resins or volatile solvents. It is equipped with an explosion vent which releases explosion and a safety door to ensure security.

- Door equipped with a single-action lever

- The door can be securely locked by an easy-to-use single-action lever. Even if the operator accidentally turns on the power when door is unlocked, the door lock detection switch prevents heater fan from starting. Besides, in three minutes, the alarm buzzer sounds to call for warning.

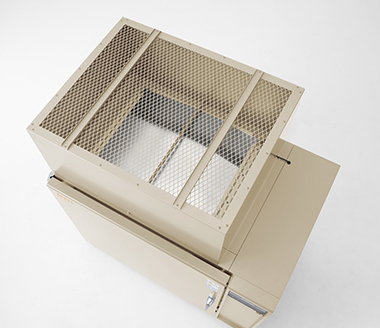

- In case an explosion occurs inside the test chamber, as shown in the above image, insulation material is bent and blown upward together with the aluminium plate to the metal screen at the top of the chamber.

This way the explosion is safely channeled and released through the top metal screen. For SPH(H)-402, explosion is released through the top metal screen by bending insulation material on the rear wall.

- PDF Catalog (4.3MB)

- Contact us

- Customer Support Desk

Environmental

Test Chambers

- Temperature

(& Humidity) Chambers /

Rapid-Rate Thermal Cycle Chambers- Platinous J Series Temperature

(& Humidity) Chamber - Environmental Stress Chamber

AR series - Rapid-Rate Thermal Cycle Chamber

- Bench-Top Type Temperature

(& Humidity) Chamber - Constant Climate Cabinet

- Compact Ultra Low Temperature Chamber

- Stability Test Chamber (CSH)

- Stability Test Chamber (CWH)

- Walk-In Chamber E Series / High-power Series

- Highly Accelerated Stress Test System (HAST Chamber)

- Temperature

(& Humidity) Chamber FD Series - High-Rate Thermal Cycle Chamber

- VOC Emission Test Chamber

- Altitude Temperature

Chamber - Altitude Temperature

(& Humidity) Chamber - Large Highly Accelerated Stress Test System

(HAST Chamber)

- Platinous J Series Temperature

- Thermal Shock Chambers

- Air to Air Thermal Shock Chambers

Fixed test area type /

Elevator type - Thermal Shock Chamber 300°C Specification

- Large Capacity Thermal Shock Chamber TSA-603EL-W

(600L) - Large Capacity Thermal Shock Chamber

- Liquid to Liquid Thermal Shock Chamber

- Large Capacity Liquid to Liquid Thermal Shock Chamber

- Air to Air Thermal Shock Chamber with Humidity

- Highly Accelerated Air to Air Thermal Shock Chamber (HAATS)

- Air to Air Thermal Shock Chambers

- Temperature Chambers

- Industrial Ovens

Temperature Chamber

Series - Industrial Ovens

Ultra-High Temperature Chamber - Industrial Ovens

Temperature Chamber

with Explosion Vent - Industrial Ovens Temperature Chamber with Rotating Specimen Rack

- Industrial Ovens Anaerobic Temerature Chamber

- Industrial Ovens Large Volume Temperature Chamber

- Desk-top Type High-Temp. Chambers

- Convection Oven

- Industrial Ovens High Performance Clean Oven

- Vacuum Oven

- Slide Tray Oven

- Large Clean Oven

- One-Pass Oven

- Anaerobic Oven

(Less than 100ppm)

- Industrial Ovens

- Network Products

- Example Custom Orders

- Combined Temperature & Humidity Chamber

- Weather Simulation Chamber

- Vertical/Horizontal Vibration Combined Environmental Test System

- Multi-axis Vibration Combined Standard Environmental

Test System - Large Highly Accelerated Stress Test System

(HAST Chamber) - Anaerobic Clean Oven

(SCO Series) - Temperature (& Humidity) Chamber with Large, Double-sided Viewing Window