Vacuum Oven

Overview of Equipment

VAC series

Fundamental equipment for electronics production

These units has been exclusively designed for vacuum heat treatment such as defoaming, deaerating, hardening or drying, essential processes in the production of electronic components.

- Eco model

- Thanks to improved air-tightness and sealing capacity, the chamber achieves 20 to 40% savings in energy consumption. (Compared to previous model)

- Program operation

- Control programs possible by combining temperature and 5 pressure operation modes.

- Variety of options

- More than 20 options are available to meet customers' needs.

Specifications

Please scroll horizontally to look at table below.

| Model | Temperature & humidity range | Inside/Outside dimensions(mm) |

|---|---|---|

| VAC-101P | +40 to +200°C (+104 to +392°F) / 933 to 1×102Pa |

W450×H450×D450 / W902×H1392×D780 |

| VAC-201P | W600×H600×D600 / W1052×H1532×D930 |

|

| VAC-301P | W800×H800×D800 / W1252×H1772×D1130 |

LCV series

Specifications

Please scroll horizontally to look at table below.

| Model | Vacuum pump |

Temperature & humidity range | Inside/Outside dimensions(mm) |

|---|---|---|---|

| LCV-234 | - | Ambient temperature to +200°C (+392°F) / 0 to -101kPa(Gauge) |

W450×H450×D450 |

| W670×H890×D735 | |||

| LCV-234P | ✓ | W450×H450×D450 | |

| W670×H1540×D735 | |||

| LCV-244 | - | W550×H550×D550 | |

| W770×H990×D835 | |||

| LCV-244P | ✓ | W550×H550×D550 | |

| W770×H1640×D835 |

Features

VAC series

- Uncompromising energy-saving mechanisms

- Max. 40% of energy savings can be achieved through various structure improvements: superior insulation materials' use, enhanced door lock, etc. for better insulation and air-tightness.

- Flexible programming of the operation mode

- A wide variety of programs can be designed by combining constant and programmed temperature operations with one of the 5 pressure operation modes (Automated operation, continuous operation, open to atmosphere, gas exchange, and ventilation operation) Up to 40 patterns can be set, with 99 steps per pattern programmable.

- Double-layered interior construction

- The interior of the vacuum chamber is equipped of a double structure. A heater surrounding the internal chamber allows great uniformity performance by minimizing heat loss.

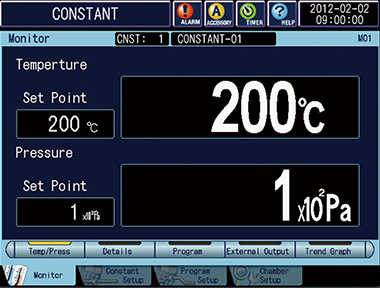

- Revamp high-speed processing controller

- User-friendly configuration allows easy operation of the different commands. Bright touch panel with speedy information processing.

- Register test patterns

- Up to 40 patterns for program operation and 3 patterns for constant operation can be registered.

- Broad range of options

- Over 20 options available to best suit your application.

- Expert Mode (Option)

- Control of the pressure increase / decrease can be achieved in 6 stages; an operation is memorized when performed the first time and can be called up to accurately repeat the process.

- Viewing window (Option)

- Slightly curved viewing window, eliminating any exterior reflection.

- P-Instrumentation

- Pressure operation (Expert Mode)

- Viewing window

LCV series

- Direct heating system for fast vacuum-dry

- In addit ion to the ga s exchange function, it can treat specimens in oxygen-free atmospheres using nitrogen or other gases, and supports baking, degassing, hardening, deaeration and numerous other applications.

- Easy operation

- Temperature setting and upper/lower temperature limit alarm setting can be done with simple key operation.

- PDF Catalog (3.5MB)

- Contact us

- Customer Support Desk

Environmental

Test Chambers

- Temperature

(& Humidity) Chambers /

Rapid-Rate Thermal Cycle Chambers- Platinous J Series Temperature

(& Humidity) Chamber - Environmental Stress Chamber

AR series - Rapid-Rate Thermal Cycle Chamber

- Bench-Top Type Temperature

(& Humidity) Chamber - Constant Climate Cabinet

- Compact Ultra Low Temperature Chamber

- Stability Test Chamber (CSH)

- Stability Test Chamber (CWH)

- Walk-In Chamber E Series / High-power Series

- Highly Accelerated Stress Test System (HAST Chamber)

- Temperature

(& Humidity) Chamber FD Series - High-Rate Thermal Cycle Chamber

- VOC Emission Test Chamber

- Altitude Temperature

Chamber - Altitude Temperature

(& Humidity) Chamber - Large Highly Accelerated Stress Test System

(HAST Chamber)

- Platinous J Series Temperature

- Thermal Shock Chambers

- Air to Air Thermal Shock Chambers

Fixed test area type /

Elevator type - Thermal Shock Chamber 300°C Specification

- Large Capacity Thermal Shock Chamber TSA-603EL-W

(600L) - Large Capacity Thermal Shock Chamber

- Liquid to Liquid Thermal Shock Chamber

- Large Capacity Liquid to Liquid Thermal Shock Chamber

- Air to Air Thermal Shock Chamber with Humidity

- Highly Accelerated Air to Air Thermal Shock Chamber (HAATS)

- Air to Air Thermal Shock Chambers

- Temperature Chambers

- Industrial Ovens

Temperature Chamber

Series - Industrial Ovens

Ultra-High Temperature Chamber - Industrial Ovens

Temperature Chamber

with Explosion Vent - Industrial Ovens Temperature Chamber with Rotating Specimen Rack

- Industrial Ovens Anaerobic Temerature Chamber

- Industrial Ovens Large Volume Temperature Chamber

- Desk-top Type High-Temp. Chambers

- Convection Oven

- Industrial Ovens High Performance Clean Oven

- Vacuum Oven

- Slide Tray Oven

- Large Clean Oven

- One-Pass Oven

- Anaerobic Oven

(Less than 100ppm)

- Industrial Ovens

- Network Products

- Example Custom Orders

- Combined Temperature & Humidity Chamber

- Weather Simulation Chamber

- Vertical/Horizontal Vibration Combined Environmental Test System

- Multi-axis Vibration Combined Standard Environmental

Test System - Large Highly Accelerated Stress Test System

(HAST Chamber) - Anaerobic Clean Oven

(SCO Series) - Temperature (& Humidity) Chamber with Large, Double-sided Viewing Window