Multi-axis Vibration Combined Environmental Test System

Overview of Equipment

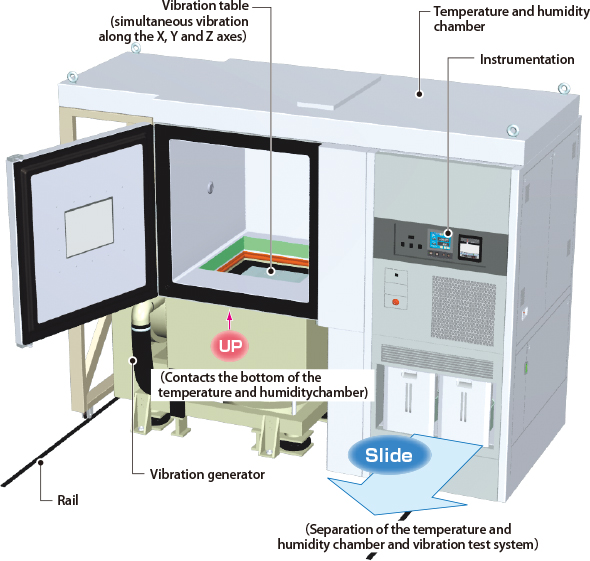

(Vertical and horizontal) temperature, humidity and vibration combined environmental test system

Reproducing more realistic field condition with simultaneous vibration along the X, Y and Z axes

Today, the automotive industry accelerates electronic multi-functions. According to this trend, safety standards such as ISO26262 and IEC61508 require high environmental stress that is generated by thermal shock chambers for higher reliability of vehicle equipments.

The Multi-axis Vibration Combined Environmental Test System is a environmental test system that combines a temperature and humidity chamber and multi-axis vibration test system. This model uses a multi-axis vibration test system, which enables simultaneous vibration along the X, Y and Z axes in the vibration equipment, thereby eliminating the need to change samples when changing the vibration axis (X, Y and Z axes) and reproducing a vibration environment similar to that in which the sample is actually used. With these advantages, this chamber is the ideal test system for performing combined environmental tests on automotive parts and car electronics products and parts.

- Improved test efficiency by eliminating switch vibration axes

- With a vibration device in which vertical (Z axis) and horizontal (X/Y axes) vibration are performed using separate tables, changing from a vertical vibration test to a horizontal test requires switching the power transmission from the vibration generator from the Z axis to the X and Y axes, and the sample must be moved from the vertical table to the horizontal table at the same time. This chamber, however, can perform both vertical and horizontal vibration on one table, thereby preventing a waste of time due to stopping of the test. Testing can also be automated for more efficient work.

- Ideal for drive simulations with a more realistic vibration environment

- To evaluate whether automotive parts functions properly, the parts must be subjected simultaneously to environmental factors, such as temperature, humidity and vibration, similar to the actual field condition, and mutually-induced flaws must also be checked.

- Independent testing of temperature/humidity and vibration (simultaneously along the X, Y and Z axes)

- With a separate temperature and humidity chamber and multi-axis vibration test system, this device can perform temperature characteristic testing with the temperature and humidity chamber and vibration testing simultaneously along the X, Y and Z axes. (See "Device mechanism" below)

- Safety devices

- It is possible to equip the system with safety devices for testing flammable or gaseous specimens, including rechargeable batteries and fuel cells.

-

Typical devices:

- Pressure release vent

- Gas detector

- Forced ventilation system

- CO2 gas extinguisher

- Safety lock mechanism

-

* Be sure to install the safety device if the specimens are Li-ion battery packs or Li-ion battery modules.

- Device mechanism

Main specifications

Please scroll horizontally to look at table below.

| Model | PVL-5KPH | ||

|---|---|---|---|

| Temperature and humidity chamber | Performance | Temperature range | -40°C to +150°C |

| Humidity range | 20 to 98%rh | ||

| Temperature heat-up time | Within 80 minutes from -40°C to +150°C | ||

| Temperature pull-down time | Within 100 minutes from +20°C to -40°C | ||

| Dimensions | Inside dimensions | W1000×H1000×D1000mm | |

| Outside dimensions | W3275×H2412×D1368mm | ||

| Combination | Combined system | Direct coupling to the chamber floor method | |

| Combination range | Vibration test system 2.9 kN to 80 kN | ||

| Vibration device | Performance | Force | 9.8 kN (1000 kgf) sine |

| Frequency range | 3 to 800Hz | ||

| Maximum displacement | 51mmp-p | ||

| Maximum velocity | 1.2m/s | ||

| Maximum acceleration | 122m/s² | ||

| Vibration table | 500×500mm | ||

- * The model is for operational purposes and may be changed after order. Thank you for your understanding.

- * The specifications of vibration devices (sign wave vibration test(fixed-frequency vibration, sweep vibration), random vibration test, shock test) will be adjusted according to the requirements of individual customers.

- * The most suitable method will be proposed considering the customer's installation space and the requirements for coupling the system with the vibration generator (method: direct coupling to the chamber floor/coupling shaft, vibration: horizontal/vertical).

Recommended products for customers viewing this product

- Contact us

- Customer Support Desk

Environmental

Test Chambers

- Temperature

(& Humidity) Chambers /

Rapid-Rate Thermal Cycle Chambers- Platinous J Series Temperature

(& Humidity) Chamber - Environmental Stress Chamber

AR series - Rapid-Rate Thermal Cycle Chamber

- Bench-Top Type Temperature

(& Humidity) Chamber - Constant Climate Cabinet

- Compact Ultra Low Temperature Chamber

- Stability Test Chamber (CSH)

- Stability Test Chamber (CWH)

- Walk-In Chamber E Series / High-power Series

- Highly Accelerated Stress Test System (HAST Chamber)

- Temperature

(& Humidity) Chamber FD Series - High-Rate Thermal Cycle Chamber

- VOC Emission Test Chamber

- Altitude Temperature

Chamber - Altitude Temperature

(& Humidity) Chamber - Large Highly Accelerated Stress Test System

(HAST Chamber)

- Platinous J Series Temperature

- Thermal Shock Chambers

- Air to Air Thermal Shock Chambers

Fixed test area type /

Elevator type - Thermal Shock Chamber 300°C Specification

- Large Capacity Thermal Shock Chamber TSA-603EL-W

(600L) - Large Capacity Thermal Shock Chamber

- Liquid to Liquid Thermal Shock Chamber

- Large Capacity Liquid to Liquid Thermal Shock Chamber

- Air to Air Thermal Shock Chamber with Humidity

- Highly Accelerated Air to Air Thermal Shock Chamber (HAATS)

- Air to Air Thermal Shock Chambers

- Temperature Chambers

- Industrial Ovens

Temperature Chamber

Series - Industrial Ovens

Ultra-High Temperature Chamber - Industrial Ovens

Temperature Chamber

with Explosion Vent - Industrial Ovens Temperature Chamber with Rotating Specimen Rack

- Industrial Ovens Anaerobic Temerature Chamber

- Industrial Ovens Large Volume Temperature Chamber

- Desk-top Type High-Temp. Chambers

- Convection Oven

- Industrial Ovens High Performance Clean Oven

- Vacuum Oven

- Slide Tray Oven

- Large Clean Oven

- One-Pass Oven

- Anaerobic Oven

(Less than 100ppm)

- Industrial Ovens

- Network Products

- Example Custom Orders

- Combined Temperature & Humidity Chamber

- Weather Simulation Chamber

- Vertical/Horizontal Vibration Combined Environmental Test System

- Multi-axis Vibration Combined Standard Environmental

Test System - Large Highly Accelerated Stress Test System

(HAST Chamber) - High Speed Clean Oven (HSC Series)

- Anaerobic Clean Oven

(SCO Series) - LCD/OLED Macro Aging Test Chamber (LBC Series)

- Temperature (& Humidity) Chamber with Large, Double-sided Viewing Window