![]()

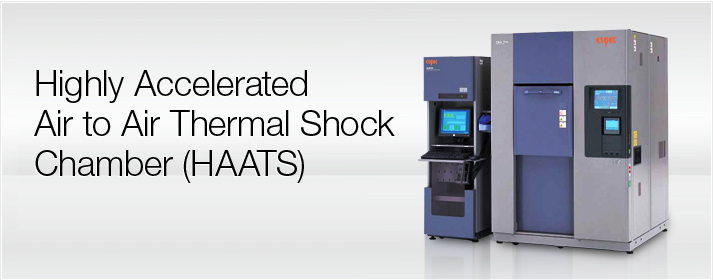

Today, the automotive industry accelerates electronic multi-functions. According to this trend, safety standards such as ISO26262 and IEC61508 require high environmental stress that is generated by thermal shock chambers for higher reliability of vehicle equipments.

Acceerlated temp. recovery time -perfect for quick evaluation of solder crack

As product reliability demands and testing time for stress tests are increasing, product development time is decreasing.

This model combines the newly developed highly accelerated air to air thermal shock chamber, which has reduced thermal shock testing time by one-third, with a conductor resistance evaluation system, which evaluates the reliability of connectors on print substrates and electronic parts. As a result, development time can be reduced and power consumption can be economized.

- Features

-

<Highly Accelerated Air to Air Thermal Shock Chamber>

-

Obtain test results that correlate with a conventional thermal shock test.

*1 Coffin-Manson evaquation is used for this thermal shock testing. The relationship between the life cycle and the temperature change is expressed in the following formula.

L=A(ΔT)-n

L=Life cycle

A=Constant

ΔT=Temperature change

n=Temperature cycle acceleration factor

This explains that the exposure time has no effect on the evaluation results. The same results have been observed in sample tests which ESPEC conducted independently. - High velocity and unique air flow control enable a temperature recovery time of 3 minutes between +125°C and -40°C. It reduces thermal shock testing time by one-third for significantly faster testing.

- Frost-free circuit prevents the formation of frost, thereby eliminating the need to stop a test and perform defrosting.

It reduces the time and power consumption used for defrosting. - With wind velocity controller allows control of wind velocity, a chamber enables conventional thermal shock testing.

-

-

<Conductor Resistance Evaluation System>

- Constantly measure micro current and micro resistance during thermal shock tests to accurately obtain the absolute value and rate of change to determine failures.

- Available from a direct current measurement system and an alternating current measurement system.

- Test cases of confirming validity of velocity (one-third the exposure time of conventional test)

-

Highly accelerated thermal cycle test

(air chamber)Conventional thermal cycle test

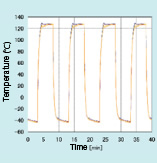

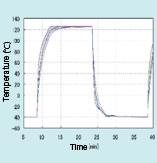

(air chamber)Temperature range -40°C ⇔ +125°C(⊿t=165°C) Exposure time 5 minutes 15 minutes Temperature profile

Hot

(+123°C or more)Cold

(-38°C or less)Hot

(+123°C or more)Cold

(-38°C or less)Substrate temperature

recovery time1.1 to 1.3 minutes 1.5 to 2.5 minutes Substrate temperature

recovery time3.4 to 7.9 minutes 3.7 to 6.2 minutes Substrate temperature

hold time3.7 to 3.9 minutes 3.5 to 2.5 minutes Substrate temperature

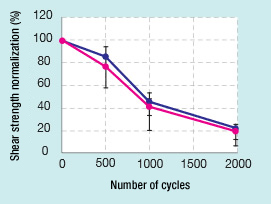

hold time7.1 to 11.6 minutes 8.8 to 11.3 minutes Proposal of a new test method

Cross-section observation

There is no notable difference in cracking or advancingHighly accelerated method

- 500cycle

- 1000cycle

- 2000cycle

Conventional method

- 500cycle

- 1000cycle

- 2000cycle

Strength test

There is no difference in the joining strength deterioration

- Specifications

-

<Highly Accelerated Air to Air Thermal Shock Chamber>

Model TSH-13-W Method Temperature recovery (highly accelerated operation) Performance High-temperature exposure +60°C to +200°C Low-temperature exposure -70°C to 0°C Temperature recovery (highly accelerated operation) High-temperature exposure: +125°C 5 minutes

Low-temperature exposure: -40°C 5 minutes

Specimen: 1.36 kg

(using a glass epoxy substrate)

Temperature recovery rate: within 3 minutesSystem Mechanical two-way refrigeration system (water cooled) Construction Inside capacity 12L Test area W300×H200×D200mm Outside dimensions W1430×H1900×D1370mm Weight Approx. 1,070 kg -

<Conductor Resistance Evaluation System (direct current measurement system)>

Model AMR-040-UD Measurement system Electric current measurement system Channel construction 40 standard channels (max. 280 channels per rack)) Channel control 10 channel unit Resistance measurement range 1.0×10(-3)~1.0×10(6)Ω Measurement range 1Ω, 10Ω, 100Ω, 1kΩ, 10kΩ, 100kΩ, 1MΩ, AUTO Measuring instrument Model:34420A (Agilent Technologies) Outside dimensions W530×H1750×D940mm -

<Conductor Resistance Evaluation System (alternating current measurement system)>

Model AMR-040-UA Measurement system Electric current measurement system Channel construction 40 standard channels (max. 280 channels per rack) Channel control 10 channel unit Resistance measurement range 1.0×10(-3)~1.0×10(6)Ω Measurement range 10mΩ, 100mΩ, 1Ω, 10Ω, 100Ω, 1kΩ, 10kΩ, AUTO Measuring instrument Model:4338B (Agilent Technologies) Outside dimensions W530×H1750×D940mm

- Examples

-

· -40°C ⇔ +125°C Test area recovery time 5 min,

exposure time 5 minSpecimen: In-vehicle DC-DC convertor · -40°C ⇔ +65°C Test area recovery time 5 min Specimen: In-vehicle battery cell

Recommended products for customers viewing this product

- Conductor Resistance Evaluation System (AMR)

- Air to Air Thermal Shock Chamber

- Large Capacity Liquid to Liquid Thermal Shock Chamber

- Thermal Shock Chamber 300°C Specification

- Large Capacity Thermal Shock Chamber 603EL (600L)

- Air to Air Thermal Shock Chamber with Humidity

- High-rate Thermal Cycle Chamber