Air to Air Thermal Shock Chambers

Overview of Equipment

TSA series (Fixed test area type - Damper type, two/three zones)

Compliant with IEC 60068-2-14 Na and MIL-STD-883L standard tests

Test area capacity: 40L to 300L

TSA How it works (1min 26sec)

- Thermal shock without moving test specimens

- TSA series is designed to evaluate reliability of test specimens by rapid change of the air temperatures from hot to cold repeatedly by opening and closing of damper in a single test area. You can get accurate test results without any mechanical impact on test specimens because a test area does not move. Fixed test area type can save testing time because transfer time of the specimen from one chamber to the other is not necessary, also suitable for testing large size, heavy specimens and/or testing many small devices at one time.

- Highly accurate temperature recovery

- The conditioned air is pre-cooled or pre-heated beyond the setpoint, allowing quicker recovery of the desired condition.

- Easy access to specimens

- Wiring to specimens is simple and easy, also the cables are supported and secured in its position because the test area does not move. Monitoring and data acquisition of test specimens is easy through cable port, too.

TSE-12 (Elevator type, two zones)

Compact type thermal shock

Test area capacity: 11L

- Optimized size for low-volume testing

- The compact thermal shock chamber answers to the need for small or low-volume specimens testing. Featuring a wide test area in a slim design, the TSE chamber offers high performances that meet severe test requirements.

- Quick temperature recovery

- The two zone test system (+150°C to -65°C) achieves temperature recovery time of less than 5 min, without auxiliary cooling.

- Meeting International Standards

- The TSE chamber achieves various tests from major international standards such as MIL, JIS…

TSD-101 (Elevator type, two zones)

Large capacity, small footprint

Test area capacity: 100L

- Uniform thermal stress performances

- The two-zone thermal shock chambers have been developed to meet major International standards for thermal shock testing.

Achieving uniform thermal stress and outstanding temperature distribution performances, the 100L test area fits for a wide range of applications in the field of research, development, inspection, and production.

- Meeting International Standards

- TSD chamber achieves various tests from major international standards such as MIL, IEC, JIS.

- Reduced power consumption

- Energy saving is a great matter for us. The TSD chamber integrates many features, such as a refrigeration capacity control, to reduce the power consumption by 30%.

- Energy Efficient Design

- Network solutions

- Control and monitor your chamber on-site or remotely,edit and transfer programs from one chamber to another,and receive email alerts even on your mobile.

Specifications

Please scroll horizontally to look at table below.

| Series | Model | Temperature range | Inside dimensions (mm) |

|---|---|---|---|

| TSA (two/three zones) |

TSA-43EL | High temp. exposure: Ambient temp. +50 to +200°C Low temp. exposure: –65 to 0°C |

W240×H460×D370 |

| TSA-73EL | W410×H460×D370 | ||

| TSA-103EL | W650×H460×D370 | ||

| TSA-203EL | W650×H460×D670 | ||

| TSA-303EL | W970×H460×D670 | ||

| TSA-73ES | High temp. exposure: +60 to +200°C Low temp. exposure: –70 to 0°C |

W410×H460×D370 | |

| TSA-103ES | W650×H460×D370 | ||

| TSA-203ES | W650×H460×D670 | ||

| TSA–73EH HIGH PERFORMANCE MODEL |

High temp. exposure: +60 to +200°C Low temp. exposure: –70 to 0°C |

W410×H460×D370 | |

| TSE (two zones) |

TSE-12-A | High temp. exposure: +60 to +200°C Low temp. exposure: -65 to 0°C |

W320×H148×D230 |

| TSD (two zones) |

TSD-101-W | High temp. exposure: +60 to +205°C Low temp. exposure: -77 to 0°C |

W710xH345xD410 |

Features

TSA series (Damper type, two/three zones)

- Highly accurate temperature recovery

-

Dampers with integrated rectifying function minimize variation in exposure conditions due to specimen position within the test area. This reduces the overall test time and shortens temperature recovery time, especially during low-temperature exposure. The uniformity in test conditions brought by this innovation also contributes to improved test reproducibility and reliability.

Air Flow

- Remote monitor and control

- No software required.

The chamber with Ethernet port can be connected to any PCs/smartphones/tablets via a web browser.

You can monitor, control the operation, and edit test profile remotely.

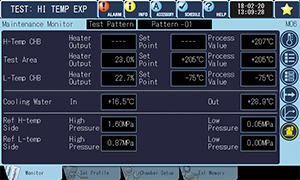

- Check the equipment on the monitor screen

- You can check the pressure of the refrigeration system and the temperature of the cooling water on the screen or PC connected to the network. This function helps operator to perform routine maintenance easily.

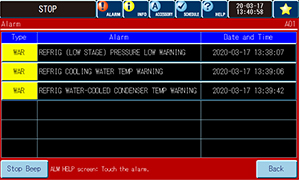

- Maintenance alert notification

- Preliminary signs of refrigeration circuit failure can be detected to avoid sudden interruption of testing. You can make a maintenance schedule before the chamber stops by alert on the maintenance screen and e-mail notification.

- Multilingual support

- The language can be switched easily on any screens.

English/Simplified Chinese/Traditional Chinese/Korean/Japanese

- 1000 cycles continuous operation

- Defrost-free operation is provided as an option so 500-hour continuous operation can be performed without interruption (if test conditions are set for 15-minute exposure).

- Highly accurate temperature recovery

- Specimen temperature control

- A single temperature sensor is attached to the specimen in the test area and the chamber is controlled by this temperature measurement.

- Specimen temperature monitor with trigger function

- Two temperature sensors are attached to the specimen in the test area to measure the specimen's temperature.

- 1000cycles (500-hour) test time

comparison example

- The newly developed refrigeration system

- To reduce thermal stress on the refrigerators and prevent corrosion in the circuit, the material and thickness of piping has been changed and this prevents refrigerant leaks.

- Enhanced test halt preset function

- It is now possible to program tests to halt after cycle or exposure completion. Six cycle counters are also built-in to the instrumentation so a test halt preset can be programmed for each counter.

- Automatic setting of pre-cooling and pre-heating in energy saving, Eco operation mode Patent JP 5204808

- The new series incorporates an algorithm that calculates the minimum operation time for pre-cooling and pre-heating by constantly measuring the amount of heat required for these processes in eco operation mode. This feature can further reduce power consumption and remove the inaccuracies and hassles caused by adjustments based on preliminary experiments.

- Parallel refrigerator control system for energy-saving control Patent JP 5487167

- The chamber can operate at the optimal refrigeration capacity based on the controlled temperature, by switching operation between two refrigerators simultaneously or a single refrigerator. At stable low-temperature exposures, power consumption is also reduced by limiting refrigeration capacity with an electronic expansion valve.

- Power consumption amount comparison example

TSE-12 (Elevator type, two zones)

- Test Standard Conformance

-

- Meets strict Mil-Std 883 1010.8 thermal cycling requirements with 4 kg.

- Also conformed to IEC 60068-2-14 Na, IEC61747-5.

- User-friendly Touch Panel Operation

-

- Operation control is done via touch panel. Very easy to use, yet full-featured.

- Simple Utility

-

- The only required utility is power supply.

- The cold zone is cooled by refrigeration. No need for tanks of liquid nitrogen (or cooling water supply).

- Quiet Operation

-

- Super quiet operation emitting noise of less than 60dB.

TSD-101 (Elevator type, two zones)

- Remote monitor and control

- No software required.

The chamber with Ethernet port can be connected to any PCs/smartphones/tablets via a web browser.

You can monitor, control the operation, and edit test profile remotely. - Short temperature recovery time

- The two temperature zone system achieves quick specimen temperature recovery time (less than 15 min. for 10kg of ICs, at extreme temperature exposure).

- Excellent temperature uniformity

- Uniform airflow in test area allows outstanding temperature distribution.

It applies uniform thermal stress to specimen and contributes accurate test results.

- Test conditions

- High temp. exposure: +155°C for 30 min.

Low temp. exposure: -68°C for 30 min.

Specimens: ICs, 10 kg - Temperature uniformity measurement method

- Thermocouples were embedded in 10 ICs placed on two levels in each of the corners and in the center of a specimen basket. (Specimens with embedded thermocouples were placed beneath other ICs.)

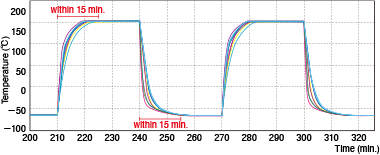

- Specimen temperature recovery (example)

(based on MIL-STD-883 Method 1010.9)

- Specimen Temperature Trigger (STT)

- TSD-101 features a STT function, monitoring the specimen to launch the exposure time or going on to following step during test. Overall test duration is reduced by eliminating pretest procedures and temperature is attained with even more accuracy.

- Ambient temperature recovery feature

- Outside air is introduced into the test area after test is complete, to quickly restore an ambient temperature and remove specimens safely.

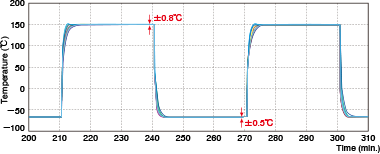

- Test conditions

- High temp. exposure: +150°C for 30 min.

Low temp. exposure: -65°C for 30 min.

Specimens: ICs (×10) - Temperature uniformity measurement method

- Thermocouples were attached to the surface of 10 ICs placed on two levels in each of the corners and in the center of a specimen basket.

- Temperature uniformity performance (example)

- Viewing window (option)

- Optional viewing window with interior lightning allows to check specimen and wiring during testing.

- Easy wiring access

- A cable port on right side allows easy wiring in specimen measurement during high and low temperature cycle test.

- Test conditions

- High temp. exposure: +150°C, 15 min. after recovery

Low temp. exposure: -65°C, 15 min. after recovery

Specimens: ICs, 10kg

Control points: Upstream of sensor positions - Measurements

- Test time reductions of approximately 15 minutes per cycle compared to other ESPEC models. For 3,000 cycles testing this cuts previous test times from 4.5 months to approximately 1 month.

- Test time comparison (example)

- Compatible test standards

-

IEC 60749-25 Semiconductor devices – Temperature cycling IEC 60068-2-14 Na Environmental testing – Change of temperature IEC 61747-5 Liquid crystal and solid-state display devices – Environmental, endurance and mechanical test methods MIL-STD-883 Military standard, microcircuits, test standards IPC-TM-650 2.6.6 Temperature cycling, printed wiring board SAE J1879 Handbook for robustness validation of semiconductor devices in automotive applications JASO-D902 Durability testing methods for automotive electronic equipment EIAJ ED-4701 Environmental and endurance test methods for semiconductor devices. (General) EIAJ ED-4702 Mechanical stress test methods for semiconductor surface mounting devices EIAJ ED-7407 Environmental and endurance test methods for CSP, BGA package on mounting condition

Larger capacity type

Environmental

Test Chambers

- Temperature

(& Humidity) Chambers /

Rapid-Rate Thermal Cycle Chambers- Platinous J Series Temperature

(& Humidity) Chamber - Environmental Stress Chamber

AR series - Rapid-Rate Thermal Cycle Chamber

- Bench-Top Type Temperature

(& Humidity) Chamber - Constant Climate Cabinet

- Compact Ultra Low Temperature Chamber

- Stability Test Chamber (CSH)

- Stability Test Chamber (CWH)

- Walk-In Chamber E Series / High-power Series

- Highly Accelerated Stress Test System (HAST Chamber)

- Temperature

(& Humidity) Chamber FD Series - High-Rate Thermal Cycle Chamber

- Altitude Temperature

Chamber - Altitude Temperature

(& Humidity) Chamber

MZ Series - Large Highly Accelerated Stress Test System

(HAST Chamber)

- Platinous J Series Temperature

- Thermal Shock Chambers

- Temperature Chambers

- Industrial Ovens

Temperature Chamber

Series - Industrial Ovens

Ultra-High Temperature Chamber - Industrial Ovens

Temperature Chamber

with Explosion Vent - Industrial Ovens Temperature Chamber with Rotating Specimen Rack

- Industrial Ovens Anaerobic Temerature Chamber

- Industrial Ovens High Performance Clean Oven

- Industrial Ovens Large Volume Temperature Chamber

- Desk-top Type High-Temp. Chambers

- Convection Oven

- Vacuum Oven

- One-Pass Oven

- Anaerobic Oven

(Less than 100ppm) - Large Clean Oven

- Slide Tray Oven

- Anaerobic Clean Oven

(SCO Series)

- Industrial Ovens

- Network Products

- Example Custom Orders