Highly Accelerated Air to Air Thermal Shock Chamber

Overview

Highly Accelerated Air Thermal Shock Testing: A test method that accelerates thermal shock testing

Chamber for HAATS (Highly Accelerated Air Thermal Shock) testing

- Features

-

- Significantly shortened testing time

This chamber achieves a temperature recovery between +125°C and -40°C only in 3 minutes by high air velocity and unique air flow control which reduce testing time approximately 1/3 compared to conventional models. - Ensures correlation with thermal shock testing

Enables more efficient evaluations by retaining test accuracy. - Defrost-free with no test interruptions

No interruptions required during testing for defrosting with a defrost-free function which prevents from frost.

Saves time and power consumption for defrosting. - Available for conventional thermal shock testing

Enables to perform conventional thermal shock testing by equipping with a air flow adjuster for allowing reduction of air velocity.

Provides a variety of thermal shock testing with a variety of evaluation conditions flexibly.

- Significantly shortened testing time

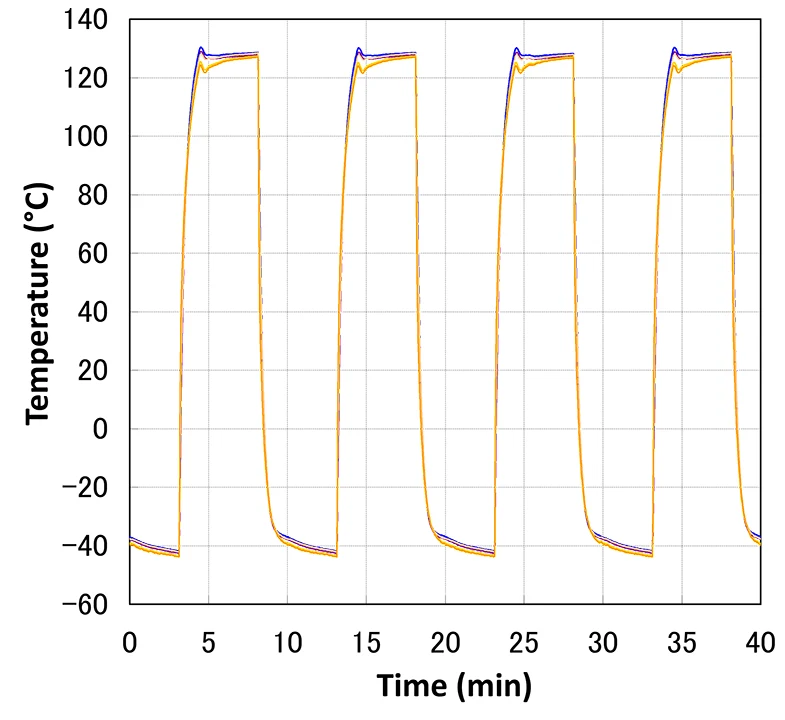

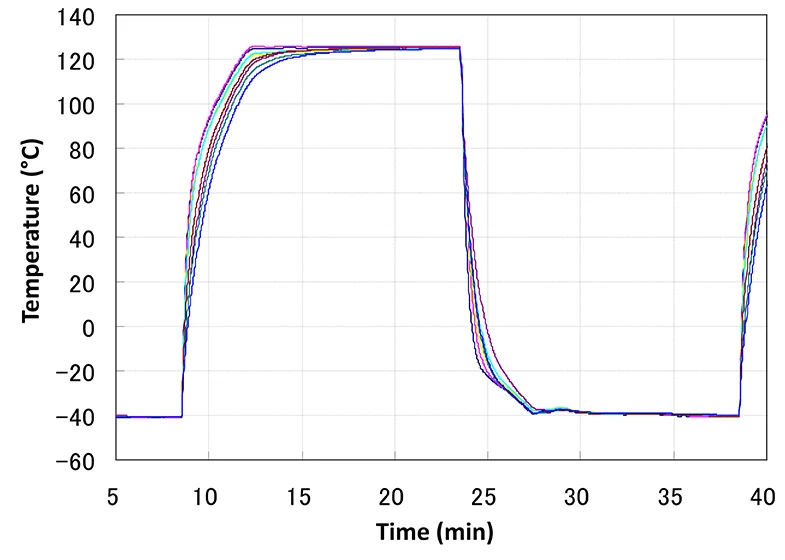

Test cases of confirming validity of velocity (one-third the exposure time of conventional test)

Please scroll horizontally to look at table below.

| Highly accelerated thermal cycle test (air chamber) |

Conventional thermal cycle test (air chamber) |

|||||

|---|---|---|---|---|---|---|

| Temperature range | -40°C ⇔ +125°C(⊿t=165°C) | |||||

| Exposure time | 5 minutes | 15 minutes | ||||

| Temperature profile |  |

|

||||

| Hot (+123°C or more) |

Cold (-38°C or less) |

Hot (+123°C or more) |

Cold (-38°C or less) |

|||

| Substrate temperature recovery time | 1.1 to 1.3 minutes | 1.5 to 2.5 minutes | Substrate temperature recovery time | 3.4 to 7.9 minutes | 3.7 to 6.2 minutes | |

| Substrate temperature hold time | 3.7 to 3.9 minutes | 3.5 to 2.5 minutes | Substrate temperature hold time | 7.1 to 11.6 minutes | 8.8 to 11.3 minutes | |

Specifications

Please scroll horizontally to look at table below.

| Model | TSH-13-W | ||

|---|---|---|---|

| Method | Temperature recovery (highly accelerated operation) |

||

| Performance | High-temperature exposure | +60°C to +200°C | |

| Low-temperature exposure | -70°C to 0°C | ||

| Temperature recovery (highly accelerated operation) |

High-temperature exposure: +125°C 5 minutes Low-temperature exposure: -40°C 5 minutes Specimen: 1.36 kg (using a glass epoxy substrate) Temperature recovery rate: within 3 minutes |

||

| System | Cascade refrigeration system | ||

| Construction | Inside capacity | 12L | |

| Test area dimensions | W300×H200×D200mm | ||

| Outside dimensions | W1430×H1900×D1370mm | ||

| Weight | Approx. 1,070 kg | ||

- Examples

-

・-40°C ⇔ +125°C Test area recovery time 5 min, exposure time 5 min Specimen: DC-DC converter for vehicle ・-40°C ⇔ +65°C Test area recovery time 5 min Specimen: Battery cell for vehicle

Recommended products

-

Conductor Resistance Evaluation System

Conductor Resistance Evaluation System

-

Air to Air Thermal Shock Chambers

Air to Air Thermal Shock Chambers

Fixed test area type /

Elevator type -

Large Capacity Liquid to Liquid Thermal Shock Chamber

Large Capacity Liquid to Liquid Thermal Shock Chamber

-

Thermal Shock Chamber 300°C Specification

Thermal Shock Chamber 300°C Specification

-

Large Capacity Thermal Shock Chamber

Large Capacity Thermal Shock Chamber

TSA-603EL-W

(600L) -

Air to Air Thermal Shock Chamber with Humidity

Air to Air Thermal Shock Chamber with Humidity

-

High-Rate Thermal Cycle Chamber

High-Rate Thermal Cycle Chamber

- Contact us

- Customer Support Desk

Environmental

Test Chambers

- Temperature

(& Humidity) Chambers /

Rapid-Rate Thermal Cycle Chambers- Platinous J Series Temperature

(& Humidity) Chamber - Environmental Stress Chamber

AR series - Rapid-Rate Thermal Cycle Chamber

- Bench-Top Type Temperature

(& Humidity) Chamber - Constant Climate Cabinet

- Compact Ultra Low Temperature Chamber

- Stability Test Chamber (CSH)

- Stability Test Chamber (CWH)

- Walk-In Chamber E Series / High-power Series

- Highly Accelerated Stress Test System (HAST Chamber)

- Temperature

(& Humidity) Chamber FD Series - High-Rate Thermal Cycle Chamber

- Altitude Temperature

Chamber - Altitude Temperature

(& Humidity) Chamber

MZ Series - Large Highly Accelerated Stress Test System

(HAST Chamber)

- Platinous J Series Temperature

- Thermal Shock Chambers

- Temperature Chambers

- Industrial Ovens

Temperature Chamber

Series - Industrial Ovens

Ultra-High Temperature Chamber - Industrial Ovens

Temperature Chamber

with Explosion Vent - Industrial Ovens Temperature Chamber with Rotating Specimen Rack

- Industrial Ovens Anaerobic Temerature Chamber

- Industrial Ovens High Performance Clean Oven

- Industrial Ovens Large Volume Temperature Chamber

- Desk-top Type High-Temp. Chambers

- Convection Oven

- Vacuum Oven

- One-Pass Oven

- Anaerobic Oven

(Less than 100ppm) - Large Clean Oven

- Slide Tray Oven

- Anaerobic Clean Oven

(SCO Series)

- Industrial Ovens

- Network Products

- Example Custom Orders