Industrial Ovens High Performance Clean Oven

Overview of Equipment

ISO Class 5 clean oven

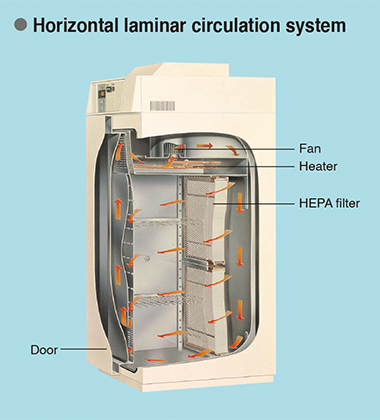

Thanks to HEPA filters, and an horizontal laminar circulation system, baking, heat treatment or drying of components requiring clean air conditions can be conducting in our High Performance Clean Oven.

The PVHC model provides stable performance even during heat up or pull down at high temperatures of +150°C or more.

- Zero contamination test area

- All internal joints are welded to ensure an airtight structure, and prevents insulation materials' leak from joints.

- Instrumentation according to applications

- Standard instrumentation or M-instrumentation available, from simple heat-treatment application to more elaborated temperature-characteristics testing.

Specifications

Please scroll horizontally to look at table below.

| Model | Temperature range | Inside/Outside dimensions(mm) |

|---|---|---|

| PVC-212 | Ambient temp. +60°C (+108°F) to +200°C (+392°F) |

W580×H530×D580 / W770×H1280×D1025 |

| PVC-232 | W580×H1130×D580 / W770×H1880×D1025 |

|

| PVC-332 | W800×H1130×D750 / W1030×H1880×D1210 |

|

| PVHC-212 | Ambient temp. +60°C (+108°F) to +350°C (+662°F) |

W580×H530×D580 / W770×H1280×D1025 |

| PVHC-232 | W580×H1130×D580 / W770×H1880×D1025 |

|

| PVHC-332 | W800×H1130×D750 / W1030×H1880×D1210 |

|

| PVHC-232MS | Ambient temp. +60°C (+108°F) to +300°C (+572°F) |

W580×H1130×D530 / W770×H1880×D1025 |

| PVHC-332MS | W800×H1130×D700 / W1030×H1880×D1210 |

- * Please contact us when using in a clean room.

- * Specify M-instrumentation for temperature programs with three or more steps.

Features

- Class 5 cleanliness level

- Class 5 cleanliness level is achieved by employing HEPA filters and a back-tofront horizontal laminar circulation system which produces uniform hightemperature airflow.

Distance of airflow in the chamber is shortened, resulting in smooth air delivery in between specimens and uniform heat treatment. Additionally, it prevents dust generated from specimens placed upstream from flowing downstream.

The upr ight design with ins t r umentation, heater, and other mechanisms gathered on the upper side saves installation space. - Airtight structure ensures zero contamination

- All internal seams are welded to create an airtight structure. This prevents leakage of insulation materials from joints which would lead to chamber contaminat ion. Vibrat ion is also eliminated from affecting the specimens.

- Highly precise non-oxidative environment

- Heat treatment and temperature character istic tests in any desired nonoxidized environment are possible thanks to an O2 concentration indication adjuster with oxygen sensor (optional) and an N2 gas injector (optional).

- Automated operation throughout heat treatment process (High-performance model)

- An automatic damper is provided as standard for automation in all processes from temperature heat-up to heat treatment and temperature pull-down.

- High level of cleanliness during temperature heat-up and pull-down (High-performance model)

- The high-performance model delivers dedicated cleanliness throughout wide temperature ranges by employing HEPA filters which provide stable filtering even during temperature changes above +150°C. Useful for heat treatment in liquid crystal production lines.

* The performance levels are given as representative examples.

Environmental

Test Chambers

- Temperature

(& Humidity) Chambers /

Rapid-Rate Thermal Cycle Chambers- Platinous J Series Temperature

(& Humidity) Chamber - Environmental Stress Chamber

AR series - Rapid-Rate Thermal Cycle Chamber

- Bench-Top Type Temperature

(& Humidity) Chamber - Constant Climate Cabinet

- Compact Ultra Low Temperature Chamber

- Stability Test Chamber (CSH)

- Stability Test Chamber (CWH)

- Walk-In Chamber E Series / High-power Series

- Highly Accelerated Stress Test System (HAST Chamber)

- Temperature

(& Humidity) Chamber FD Series - High-Rate Thermal Cycle Chamber

- Altitude Temperature

Chamber - Altitude Temperature

(& Humidity) Chamber

MZ Series - Large Highly Accelerated Stress Test System

(HAST Chamber)

- Platinous J Series Temperature

- Thermal Shock Chambers

- Temperature Chambers

- Industrial Ovens

Temperature Chamber

Series - Industrial Ovens

Ultra-High Temperature Chamber - Industrial Ovens

Temperature Chamber

with Explosion Vent - Industrial Ovens Temperature Chamber with Rotating Specimen Rack

- Industrial Ovens Anaerobic Temerature Chamber

- Industrial Ovens High Performance Clean Oven

- Industrial Ovens Large Volume Temperature Chamber

- Desk-top Type High-Temp. Chambers

- Convection Oven

- Vacuum Oven

- One-Pass Oven

- Anaerobic Oven

(Less than 100ppm) - Large Clean Oven

- Slide Tray Oven

- Anaerobic Clean Oven

(SCO Series)

- Industrial Ovens

- Network Products

- Example Custom Orders