Anaerobic Oven

(Less than 100ppm)

Overview

In recent years, wiring material has been changing from aluminum to copper with low resistivity.

Accordingly, when heat processed in a normal chamber, copper parts oxidize, leading to flaws.

In addition, aging at 250°C is performed to inspect whether the written data on flash memory is deleted with electromigration, and bump parts oxide, so the oxygen concentration must be lowered to less than 100 ppm.

This Anaerobic Oven was developed to meet these demands. Aging tests at 350°C can be performed with an oxygen concentration of 100 ppm or less.

- Significant reduction in nitrogen gas use

- This model features a high air tight design of the chamber and nitrogen gas flow rate switching mechanism to significantly reduce the amount of nitrogen gas used.

- Reduced temperature pull-down time for reduced processing time

- This model uses an innovative chamber cooling mechanism to reduce the temperature pull-down time by one-third when compared to conventional models. (Reference value: lowered from 240 minutes to 80 minutes) As a result, specimens can be more quickly removed, and processing time can be reduced.

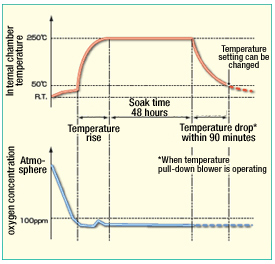

- Profile (example)

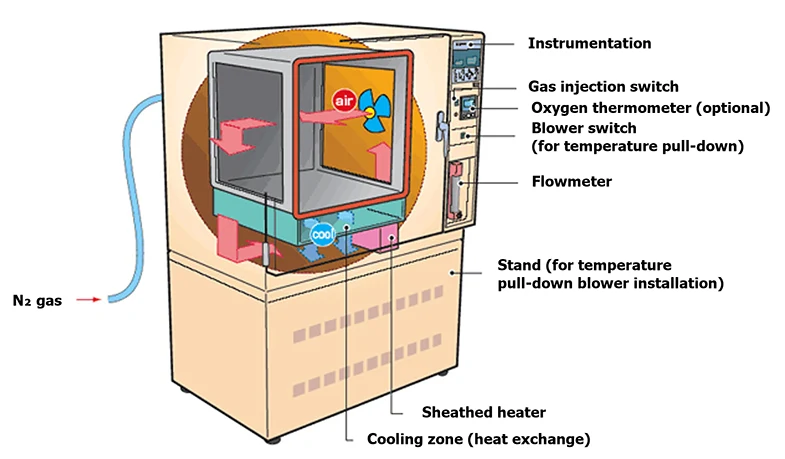

- Chamber structure

Main specifications

Please scroll horizontally to look at table below.

| Model | IPHH-202L | |

|---|---|---|

| Power supply | 200V AC φW 50/60Hz *Supporting any power supply voltage as an option |

|

| Maximum power consumption | 4.4kVA | |

| Method | Forced hot air circulation | |

| Performance | Temperature range | (Rt.+50)℃ to 300℃ |

| Temperature fluctuation range | ±0.2°C at 150°C or lower ±0.3°C at 300°C or lower |

|

| Temperature uniformity | ±1.5°C at 150°C or lower ±2.5°C at 300°C or lower |

|

| Temperature heat-up time | Within 70 minutes from +50°C to +300°C | |

| N2 gas | Gas | N2 gas (ambient temp. dry gas) |

| Min. oxygen concentration | 100 ppm or less (N2 gas injection at 40~200 L/min) | |

| Gas injection | Mouthpiece ring joint 3/8-inch pipe fitting | |

| Inside capacity | 216 L | |

| Dimensions | Inside dimensions | W600×H600×D600mm (excluding protrusions) |

| Outside dimensions | W1190×H1711×D1040mm (excluding protrusions) | |

| Weight | 250 kg | |

| Instrumentation | Operation mode | Constant operation, program operation |

| Setting and indication ranges | Temperature: 0 to +310°C Time: 0 to 9999 hours 59 minutes |

|

| Setting and indication resolution | Temperature: 1°C Time: 1 minute |

|

- * Performance is without a specimen at an ambient temperature of +23°C.

- * The model is for operational purposes and may be changed after order. Thank you for your understanding.

Recommended products

- Contact us

- Customer Support Desk

Environmental

Test Chambers

- Temperature

(& Humidity) Chambers /

Rapid-Rate Thermal Cycle Chambers- Platinous J Series Temperature

(& Humidity) Chamber - Environmental Stress Chamber

AR series - Rapid-Rate Thermal Cycle Chamber

- Bench-Top Type Temperature

(& Humidity) Chamber - Constant Climate Cabinet

- Compact Ultra Low Temperature Chamber

- Stability Test Chamber (CSH)

- Stability Test Chamber (CWH)

- Walk-In Chamber E Series / High-power Series

- Highly Accelerated Stress Test System (HAST Chamber)

- Temperature

(& Humidity) Chamber FD Series - High-Rate Thermal Cycle Chamber

- Altitude Temperature

Chamber - Altitude Temperature

(& Humidity) Chamber

MZ Series - Large Highly Accelerated Stress Test System

(HAST Chamber)

- Platinous J Series Temperature

- Thermal Shock Chambers

- Temperature Chambers

- Industrial Ovens

Temperature Chamber

Series - Industrial Ovens

Ultra-High Temperature Chamber - Industrial Ovens

Temperature Chamber

with Explosion Vent - Industrial Ovens Temperature Chamber with Rotating Specimen Rack

- Industrial Ovens Anaerobic Temerature Chamber

- Industrial Ovens High Performance Clean Oven

- Industrial Ovens Large Volume Temperature Chamber

- Desk-top Type High-Temp. Chambers

- Convection Oven

- Vacuum Oven

- One-Pass Oven

- Anaerobic Oven

(Less than 100ppm) - Large Clean Oven

- Slide Tray Oven

- Anaerobic Clean Oven

(SCO Series)

- Industrial Ovens

- Network Products

- Example Custom Orders