Energy Device Environmental Test Center

- Test facility summary/features

-

A new laboratory testing service facility created at the site of the Utsunomiya Test Center, and specializing in reliability tests/safety tests of energy devices (solar batteries, secondary batteries, power semiconductors). The world's first test facility able to evaluate all devices for power generation, storage and control.

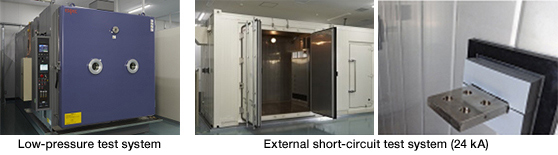

The rise of eco-friendly vehicles such as hybrids and electric vehicles is seeing growing demand for environmental tests of devices such as secondary batteries and power semiconductors. For example, demand is growing for external short-circuit tests, nail penetration tests and other types of safety tests to ensure the high safety and stable performance needed by vehicle secondary batteries. A new building with safety equipment was constructed to meet this demand. The Center meets client demand for external short-circuit tests with a lineup of the latest equipment developed in-house, including the world's first unit able to support a maximum current of 24 kA.

| Opened | November 2013 |

| Test facility area | 720m² |

| Concept | A test facility specializing in devices for power generation, storage and control |

| Structure | Safety testing room for module/pack batteries 9m×10m 3 testing rooms Safety testing room for cell batteries 12m×16m 1 testing room |

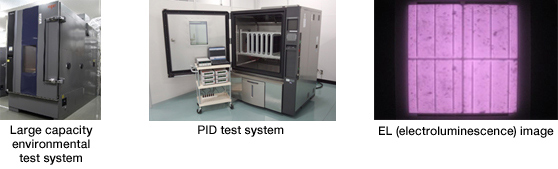

- Power generation <Solar batteries>

-

- The Center carries out many types of outsourced evaluation tests of solar batteries exposed to demanding environments. Samples ranging from material components to finished modules are evaluated.

| Design qualification test | |

| Long-term reliability testing | |

Temperature/humidity testing for compliance with IEC and other standards |

|

| Analysis/evaluations | |

Power storage <Secondary batteries>

- For charge/discharge test, the Center supports pulse tests requiring large currents (up to 360 A) or rapid variation.

- A new test unit developed in-house supports safety tests such as nail penetration tests and 24 kA external short-circuit tests (a world-first).

- Supports safety tests for compliance with the UN Recommendations on the Transport of Dangerous Goods needed for lithium-ion batteries.

- Provides safety tests, test consulting and certification services for vehicle battery packs/modules and energy storage devices.

- Provides a comprehensive range of tests/certification services for compliance with UNECE Regulation R100.

| Performance test | ||

| Safety test | Electrical test | |

| Mechanical test | ||

| Environmental test | ||

Control <Power semiconductors>

- With power devices evolving toward control of higher voltages and currents, the Center is drawing on its wealth of experience to provide power device evaluations (environmental tests, powered radiator jigs, electrical stress tests, analysis/evaluations).

| Reliability test | |

| Environmental test | Air to air thermal shock test (supporting temperatures of up to 300°C) |