HAST (Highly Accelerated Stress Test)

- Test summary/features

-

Pressure cooker testing is a test method developed for evaluating the humidity resistance of samples such as sealed plastic electronic parts.

Pressure cooker testing is used for accelerated stress testing done to evaluate the humidity resistance of electronic parts and materials. It uses high-density water vapor environments with temperatures above 100℃. The water vapor pressure in the test chamber is radically increased to a level higher than the water vapor partial pressure inside the test sample, speeding up the penetration of moisture into the test sample.

A type of pressure cooker testing called USPCT (unsaturated pressure cooker testing) is standardized by IEC 68-2-66 as HAST (Highly Accelerated Temperature and Humidity Stress Test). HAST is one method of environmental tests used for electrical and electronic parts and devices.

- Test method (summarized from IEC 68-2-66)

-

Test summary Test equipment/humidification water Does not apply to external corrosion or deformation occurring in the test sample. Temperature/humidity distribution must be within ±2°C /±5% RH. Perform testing with the normal bias applied. Condensation water must not drop onto the test sample. Select test conditions by checking their correlation with failure modes. Do not let chamber components cause deterioration of the test sample or humidification water. Pay careful attention to sealing material critical temperatures (such as the glass transition point). Select test conditions by checking their correlation with failure modes. Use distilled water or deionized water as the humidification water. Humidification water must have conductivity of 0.5 MΩ/cm or less, and pH of between 6.0 and 7.2 (at 23°C).

- Test equipment

-

The accelerated stress test equipment used for HAST has functions devised mainly for bias testing with a constant voltage or signal applied. Equipment with specimen signal terminals of up to 72 pins is available. Two equipment types are available. The two-mode models have two control modes (unsaturated control and wet saturation control). The M models have three control modes (dry/wet-bulb temperature control, unsaturated control and wet saturation control). The M models comply with IEC-60068-2-66 (an international standard).

- Equipment particulars

-

- Highly Accelerated Stress Test System (installed at Utsunomiya and Kobe Test Centers)

Main specifications

Temperature control range: +105 to 162.2°C

Humidity control range: 75 to 100%rh [Depends on temperature]

Pressure range: 0.020 to 0.392Mpa (Gauge)

Number of specimen signal terminals 72P(36ch)

-

- EHS-431M Medium-sized HAST Chamber (installed at Kobe Test Center)

-

A HAST test system supporting specimens too large to fit in conventional HAST chambers. Has about three times the capacity of conventional models, with test chamber dimensions each more than 30% larger.

Supports testing of four-cell solar battery modules that were previously untestable.

Has 72 sets of specimen signal terminals (144 pins) to support air HAST and wide-range HAST testing (both described below).Model Capacity (ℓ) Test chamber dimensions (mm) EHS-431M 130 514×514×580 EHS-221M 46 355×355×426 EHS-411M 18 255×255×318

- Other types of HAST testing

-

Air HAST and wide-range HAST are two other HAST methods available in addition to the standardized test modes (dry/wet-bulb temperature control, unsaturated control and wet saturation control). Air HAST and wide-range HAST are designed to produce reproducible test results with precise correlations to results in the field, and to minimize test times. They are described below.

- Air HAST Chamber (installed at Utsunomiya Test Center)

-

Conventional HAST testing is in widespread use as an IEC/JIS-compliant water vapor-based accelerated test method for evaluating the humidity resistance of electronic parts sealed in materials such as plastic.

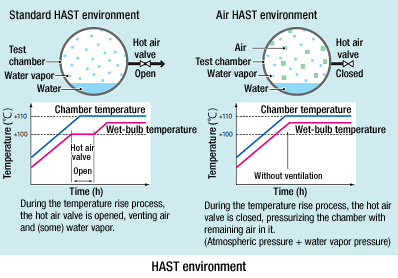

In addition to water vapor, oxygen in the air can also cause failures in the market due to oxidation near surfaces, so air HAST testing is used for some test samples and objectives. This method focuses on the air in damp heat tests. It adds air to conventional HAST tests, for accelerated testing of surface oxidation.- Test example

- Wide-range HAST Chamber (installed at Utsunomiya Test Center)

-

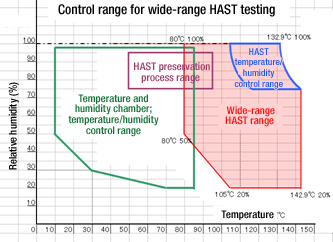

While the low temperature/humidity ranges of standard temperature/humidity chambers result in excessively long test times, temperature and humidity are too high in HAST environments. Wide-range HAST equipment was created to meet the need for equipment supporting environment testing midway between these two test environments.

Specifically, wide-range HAST testing enables damp heat tests at temperatures of around 100°C.

It supports accelerated testing of samples for which HAST testing can't be used, such as materials with moderately low glass transition points or heat resistance temperatures.

-

- Test example

-

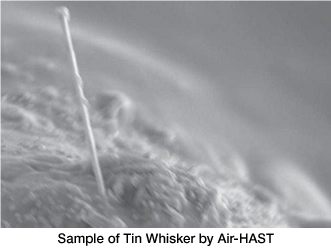

Accelerated whisker testing

Accelerated testing of coating/lighting equipment materials (LEDs, plastics) and solar panels (testing done when oxygen is considered a deterioration factor)Accelerated testing done when air may be insufficient factor for correlation with temperature/humidity testing at 85°C/85% RH