Liquid to Liquid Thermal Shock Test

- Test summary/features

-

Liquid to liquid thermal shock testing applies thermal shocks to test samples by alternately immersing them in a high- and low-temperature liquid medium. Since a liquid is used as the thermal medium, this type of testing can attain a sharper temperature variation rate than air to air thermal shock testing.

- The expansion and contraction caused by the temperature variation generate stress from differences in the expansion rates of parts made of different bonded materials. Repeated stress causes accumulated fatigue, leading to cracks and rupturing.

- The repeated action of stress causes accumulation of material fatigue, sometimes leading to rupturing at a lower strength than the static strength.

- Repeated stress can also cause coatings to peel and screws to loosen.

- Liquid to liquid thermal shock tests require caution since it can apply temperature variations that are excessively large in comparison to the various temperature variations encountered in the market, and so doesn't simulate market failures. But it is an effective thermal shock-based method of finding weaknesses.

Test equipment

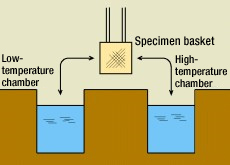

-

- As shown in the diagram, the test equipment has a high-temperature chamber and low-temperature chamber. An elevator mechanism places the specimen basket in each chamber alternately, subjecting it to thermal shock.

- The movement of the specimen basket between chambers is usually done within 10 seconds. This time can also be set.

- The liquid used is an inert liquid developed for thermal shock testing, with high electrical resistance and low surface tension.

Liquid medium normally used

Name: Galden DO2-TS

Usage temperature range: -65 to +150°C (boiling point: 165°C) - Test description

The test sample is placed in a stainless steel specimen basket, then placed in the chambers by an elevator mechanism to apply low temperature-high temperature thermal shock.

- Equipment particulars

-

- Liquid to Liquid Thermal Shock Chamber (installed at ESPEC test facilities)

| Liquid to Liquid Thermal Shock Chamber | |||

| Temperature ranges* | High-temperature exposure | +70 to +200°C | |

| Low-temperature exposure | -65 to 0°C | ||

| Test area dimensions | W150× H150× D200mm |

W215× H195× D350mm |

|

*Test temperature ranges vary according to the liquid's boiling point (high-temperature chamber) or pour point/congealing point (low-temperature chamber). A liquid (DO2-TS) supporting a temperature range of -65 to +150℃ is usually available.

- Differences between liquid to liquid- and air to air thermal shock testing

-

Since most of the temperature variations encountered in the market are relatively moderate (changing weather, power ON/OFF temperature differences), thermal cycling testing is considered beneficial.

Thermal shock testing with liquid chambers is used partly as an alternative test method to shorten test times. Its rapid temperature changes can sometimes induce failures that would be impossible in the actual operating environment, so care is needed when checking failure modes generated during testing.

*Air to air thermal shock test chambers are also available. Air to air thermal shock test chamber