Cell Safety Test

Test summary/features

-

Demand is growing for external short circuit tests, crushing tests and other types of safety testing to ensure the high safety and stable performance needed by vehicle secondary batteries.

ESPEC's Energy Device Environmental Test Center has several test equipment units developed in-house for safety evaluation of secondary battery cells.

This equipment can be used for safety testing for compliance with the UN Recommendations on the Transport of Dangerous Goods needed for lithium-ion batteries.

In addition to battery cell safety testing, ESPEC also provides safety testing, test consulting and certification services for vehicle battery packs/modules, along with a comprehensive range of testing/certification services for compliance with UNECE Regulation R100.

| Safety test | Electrical test | |

| Mechanical test | ||

| Environmental test | ||

- External short circuit

-

- It can handle a maximum short circuit current of 24kA.

- Testing is possible in a temperature environment of -40 to +80℃.

Resistance 1 to 120mΩ Maximum current 24kA

- External Short Circuit Test System

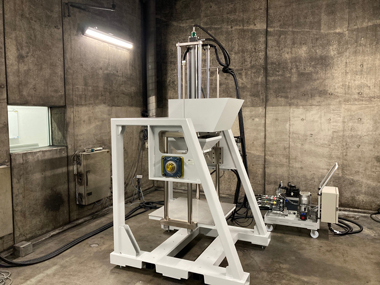

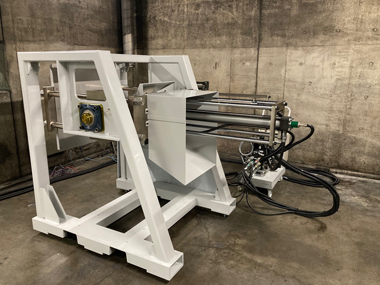

- Crush

-

Pressure release control is possible through crush tests that comply with Electrical Appliance and Material Safety Act, JIS C 8712, JIS C 8714, UN 38.3, UL1642, UL2054, etc.

When either of the following conditions occurs: maximum pressure is obtained, a sudden voltage drop is obtained to one-third of the voltage at the start of the test, or a deformation of 10% in cell height is obtained. to release the pressure.

Load 32kN (momentary maximum 50kN) Speed 1 to 81mm/s Retention time Less than 25kN:1~9999s

※ Position holding function allows

up to 24 hours.More than 25kN:2s

Stroke 600mm Crushing jig Flat plate, semicircular column (1 series), etc. Test direction Vertical / horizontal direction. Measurement Load, voltage, moving distance, speed, temperature

- Crush Test System

-

-

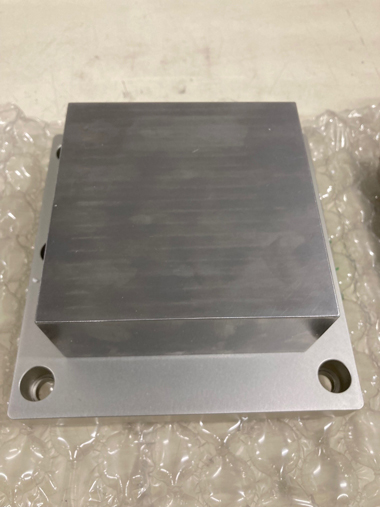

Flat plate jig -

Semicircular column

(1 series) jig

-

- Impact test

-

- Enables frictionless vertical drops.

- Supports various features such as voltage measurement and video photography.

Drop method Electromagnet method Drop weight 9.1kg Impact rod dimensions 15.8 (diameter) × 340 mm, other Impact rod material SUS316

- Impact Test System

- Low-pressure test (altitude simulation)

-

- Full range of safety features provided. Supports testing in compliance with air-transport standards (UN, UL and JIS standards).

Combined Sequential Cold, Low Air Pressure and Damp Heat Test

- Low Air Pressure Test System

- Nail penetration

-

- Compatible with speeds from 0.01 to 163 mm/s

- Combination control of automatic stop function (voltage drop, nail penetration amount) and retention time is possible.

- Crush / Nail penetration Test System

(Vertical direction)

- Crush / Nail penetration Test System

(horizontal direction)

- Other safety test

-

ESPEC also provides other types of safety testing in compliance with various standards.

Overcharging test

Over-discharging test

Vibration test

Shock test

Heating test

Temperature test (thermal shock test)

Other environment test

- Related pages