Salt Mist, Cyclic (Sodium Chloride Solution) Test

- Test summary/features

-

Salt mist testing is used to evaluate the corrosion resistance of parts and products covered with metal materials, plated films or paint films.

Salt mist combined-cyclic testing is a widely used combined-cycle test method for reliability evaluation. It combines salt mist testing with conditions such as dry, damp, low temperature or saltwater immersion. To test products used in areas of salt damage (from sea salt particles or deicing salt in snowy regions), it is used to simulate or hasten (accelerate) market conditions, evaluating materials and components such as vehicles, vehicle exterior materials, or undercarriage components or steel.

- Test equipment

-

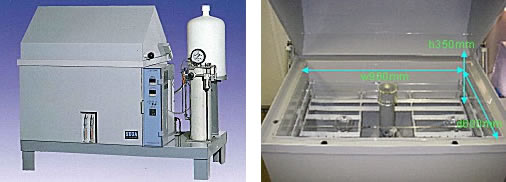

Salt mist test system and large capacity salt mist combined cyclic test system are available.

This equipment supports combined cycles that include a high-temperature (150°C) dry process, and a low-temperature (-20°C) freeze process.

- Equipment particulars

-

- Salt Mist Test System (installed at Utsunomiya Test Center)

| Main specifications | |

| Test conditions | Test temperature: 35 ± 1°C Saltwater condition: 5 ± 1% NaCl aqueous solution Test times: 16, 24, 48, 96, 168, 336 or 672 hours |

| Salt mist container dimensions | W900×D600×H350mm |

| Salt mist rate | 1.5±0.5ml/h at 80cm2 |

| Maximum test sample weight | 12 kg (evenly distributed load) |

| Supported test standards | JIS C 60068-2-11、JIS Z 2371 |

- * The chamber center has a mist tower that must be avoided when placing samples.

- * Variations in salt mist rate are expected to arise according to the sample size.

- Salt Mist Combined Cyclic Test System (installed at Toyota Test Center)

| Main specifications | ||

| Test condition ranges | Saltwater spray | 35 ± 1°C; 50 ± 1°C (neutral 5% saltwater solution; meets JIS Z2371 standard) |

| Dry | 20 to 150°C ± 1°C; humidity: 25 ± 5% RH (at 60°C) | |

| Damp | 50 to 70°C ± 1°C; humidity: 60 to 95% ± 5% RH (at 50°C) | |

| Saltwater immersion | Room temperature + 10 to 60°C ± 1°C (temperature of immersion liquid) | |

| Outside air introduction | Room temperature (no temperature/humidity control) | |

| Low temperature | -20°C (low temperature) to 20°C ± 1°C | |

| Test chamber interior dimensions | W960mm×D610mm×H860mm | |

| Number of test samples | 100 (of 150 × 70 × 3.2 (t) mm max.); placement angle: 15 or 20° | |

| Load capacity | 100 kg (when evenly distributed on floor using drainboard provided) | |

| Test record | Internal instrumentation log data | |

| Supported test standards | JIS K5621, JASO M609/M610, others | |