Electrochemical Migration Evaluation System (Leakage Current Evaluation System)

![]()

Overview of Equipment

More accurate evaluation of insulation resistance

With the advancement of AI, 5G, data centers, and other technologies, there is growing emphasis on improving the insulation reliability of board wiring technology across a wide range of low and high voltages.

This system can constantly monitor these evaluations more accurately and more efficiently. This system allows for easy and efficient evaluation of electronic component life such as electrochemical migration, as well as insulation resistance (leakage current measurement).

Specification Summary (Applied Voltage range: 1 to 100V)

Please scroll horizontally to look at table below.

| Resistance measurement range (Ω) | 2.0×105 to 1.0×1013(when 100 V is applied) 2.0×103 to 1.0×1011(when 1 V is applied) |

|

|---|---|---|

| Channel configuration | 25 to 300 ch per rack | |

| Channel control | 5ch | 25ch |

| Measurement voltage | DC1.0 to 100V (0.1V increments) | |

| Leakage current detection speed | Constant detection at less than 100 µsec | |

Features

- Tests from low-voltage to high-voltage ranges can be conducted

- The optimal stress power supply can be selected for insulation evaluation in AI, communications, and energy markets, as well as under a variety of environmental conditions.

In addition to constant stress voltages of 100 V, 300 V, and 500 V, high voltage specifications of 1000 V and 2500 V are also available. (Contact ESPEC for voltages above 2500 V.)

- Uniquely designed event detectors

- Espec original event detectors are used to monitor each and every channel.

Once the resistance drop below the predefined threshold, it will direct the measuring equipment to begin recording at a set interval.

- Improved workability and higher efficiency at regular part replacements

- By installing a connection unit, measurement cables can be easily installed and removed, improving work efficiency such as when soldering to samples. The connection unit can be installed on the front of the rack or on the left or right side depending on the installation environment.

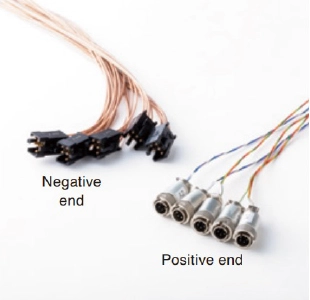

- Measurement cable

Used for each 5 ch connectors.

- Real-time monitoring of 4 environmental test chambers (via Ethernet connection)

- Up to 4 environmental test chambers can be connected and tests performed. In addition to the resistance and voltage values, linking with an environmental test chamber allows the temperature and humidity in the test area to be monitored on the AMI side. The monitoring information is recorded in the measurement result file.

- Example of connection to a Bench-top Type Temperature (& Humidity) Chamber

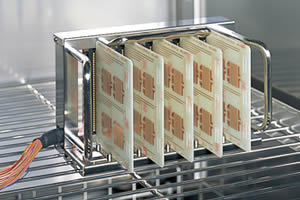

- Connecting jig (optional)

- We offer a connecting jig to best suit your specimen. It enables easy connection of specimen and cable for efficient testing.

- Connecting jig (optional)

Recommended products for customers viewing this product

Measurement & Evaluation Systems / Semiconductor-related Equipment

-

Measurement & Evaluation Systems

- Electro-chemical Migration Evaluation System(Leakage Current Evaluation System)

- High Voltage Bias Insulation Resistance Evaluation System

- Capacitor Leakage Test System

- High Temperature Reverse Bias Test System

- TDDB (Time-Dependent Dielectric Breakdown) Evaluation System

- Conductor Resistance Evaluation System

- Electromigration Evaluation System

- PV Thermal-Bias Combo Test System

- Semiconductor Parametric Test System

- Capacitor / Inductor Temperature Characteristic Evaluation System

- PV I-V Evaluation System (PV Thermal-Light Combo Test System)

- Power Cycle Test System

- Semiconductor-related Equipment