News

Meeting Testing Demand in the AI Semiconductor Market

Introducing New Walk-in Temperature & Humidity Chambers for High Heat-Generation Loads for AI Server Reliability Testing

Feb 4, 2026

ESPEC CORP. (Principal Office: Kita-ku, Osaka City; Representative Director and President: Satoshi Arata) launched two new walk-in temperature and humidity chambers for high heat-generation loads in December 2025 for AI server reliability testing. These new chambers are capable of testing under heat-generation loads of 30kW and 60kW, assuming actual server operation conditions.

As the use of generative AI expands, demand for AI servers continues to grow, and these servers play an increasingly important role in social infrastructure. At the same time, the high-performance semiconductors used in AI servers generate greater heat due to increased integration and density, resulting in increasingly harsh operating environments.

Under these conditions, demand is rising for testing to ensure reliability during AI server development and quality evaluation. In addition, ASHRAE*1 testing standards are recommended for server reliability evaluation, driving demand for equipment that both complies with these standards and supports high heat-generation loads.

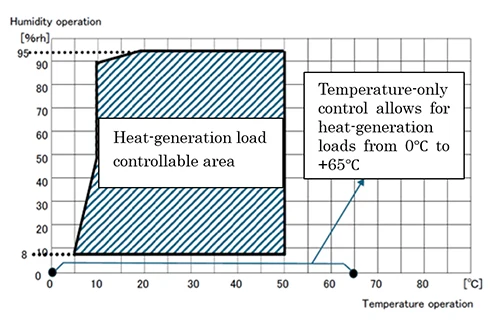

ESPEC's newly launched walk-in chambers use a proprietary control system to precisely control temperature and humidity under heat-generation loads of 30kW and 60kW, assuming AI server operation, enabling testing compliant with ASHRAE standards for server reliability evaluation. A newly adopted air circulation system also reduces the impact of exhaust heat from AI servers, ensuring a uniform temperature and humidity environment in the test area and enabling efficient testing without heat buildup. Furthermore, a newly developed air-conditioning system reduces power consumption while also achieving a more space-saving design. These products contribute to ensuring the reliability of AI servers equipped with high-performance semiconductors and power supplies that generate large amounts of heat.

As a leading manufacturer of environmental test chambers, ESPEC remains committed to providing and expanding environmentally conscious products and services that contribute to addressing challenges and supporting the advancement of advanced technology fields such as AI semiconductors and data centers.

-

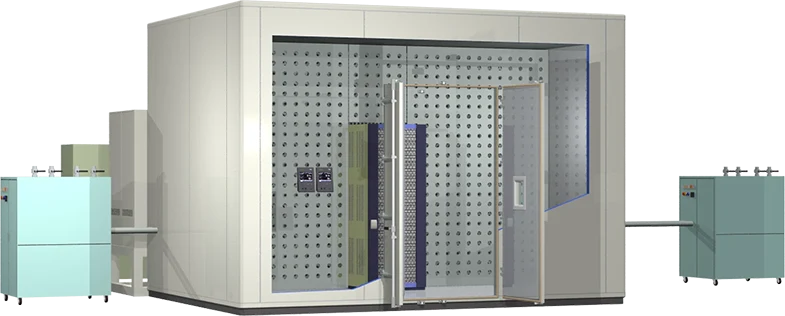

Walk-in Temperature & Humidity Chamber for High Heat-Generation Loads

■ Overview of Walk-in Temperature & Humidity Chamber for High Heat-Generation Loads

<Features>

1. Support for high heat-generation loads of AI servers

Even under high-temperature, high-humidity conditions (e.g., 40°C and 95%), the chambers maintain a uniform temperature distribution within the test area under heat-generation loads of 30kW and 60kW, assuming AI server operation.

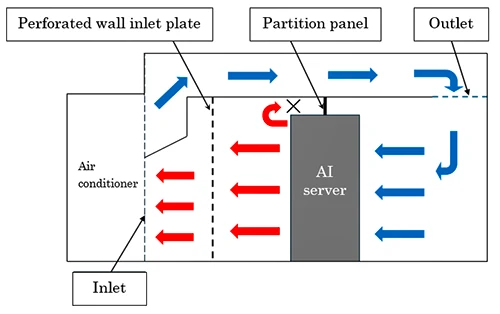

2. Uniform AI server inlet temperature distribution for standard-compliant testing

The air circulation system in the test area includes ducts in the ceiling with outlets positioned at the AI server inlet area, as well as partition panels separating the front and rear server zones. This design prevents recirculation of server exhaust heat, ensuring a uniform inlet temperature distribution and enabling testing compliant with applicable test standards. The perforated panels across the entire wall surface at the air-conditioning inlet also allow efficient recovery of exhaust heat while preventing accumulation in the test area.

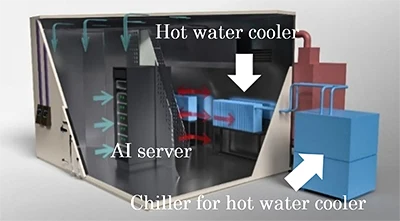

3. Newly developed air-conditioning system for improved energy and space savings

Use of standard air-conditioning systems is possible with the addition of a hot-water cooler to the existing air-conditioning system, thereby reducing the overall refrigeration equipment capacity even for high heat-generating test specimens such as AI servers. As a result, the system achieves greater energy savings and a compact footprint even with support for high heat-generation loads (patent pending).

Air conditioning system

(standard air conditioner with hot water cooler)

<Main Specifications>

| Model | 30kW type | 60kW type |

|---|---|---|

| Temperature range | -40°C to +80°C | |

| Humidity range | 8% to 95%rh (at +5°C to 50°C) |

|

| Capacity | 29m3 | 48m3 |

| Test area dimensions | W3000 × H3200 × D3000 mm | W5000 × H3200 × D3000 mm |

| Installation area | W3130 × H3655 × D3880 mm | W5130 × H3655 × D3880 mm |

- *1 ASHRAE testing standards

ASHRAE is the abbreviation for the American Society of Heating, Refrigerating and Air-Conditioning Engineers and refers to the test standards established by this organization. Tests based on these standards are conducted to evaluate whether AI servers operate properly under high-load, high-heat conditions.

■ Semiconductor-related equipment lineup

ESPEC offers a product lineup centered on "thermal solutions" for semiconductor technology development and reliability testing. Click the link below for ESPEC's products for front-end and back-end semiconductor manufacturing processes, inspection, and reliability testing.

Advanced Semiconductor Testing Equipment

Contact Details

Sustainability Management Department, ESPEC CORP.

E-mail:ir-div@espec.jp