![]()

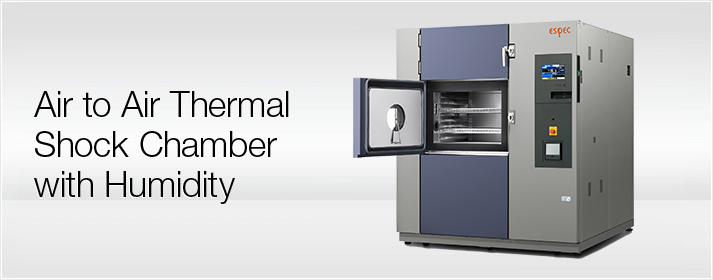

Thermal cycle testing and dew cycle testing in a single unit

Nowadays, vehicles use more and more integrated electronics and the upgrade and improvement of the multifunctional control features of microcomputers plays a great role in these. Electronic control units (ECUs), need to be reliable as it enables the control processes, providing better fuel efficiency and a safe and comfortable ride. According to this trend, safety standards such as ISO26262 and IEC61508 require high environmental stress that is generated by thermal shock chambers for higher reliability of vehicle equipments.

Mobile devices, such as laptops, smartphones, and cell phones, and electronic parts that demand has being accelerated in automotive industry (harness, ECU, PCU, etc.) are subjected to rapid temperature changes as they are moved between outside and inside environments. Naturally, these products and parts require thermal cycle testing, which repeatedly subjects them to rapid warming and cooling. Dew condensation that forms as a result of temperature changes also poses a major problem. Dew condensation can greatly affect the performance and function of electronic devices and result in corrosion, migration, or malfunction. Therefore, dew cycle testing, which repeatedly re-creates dew condensation and dry conditions is essential.

"Air to Air Thermal Shock Chamber with Humidity" is an innovative hybrid test system that enables both tests in a single unit. Two tests that have conventionally required two separate test chambers can now be performed in one unit, thereby lowering costs and space requirements.

- Innovative hybrid test system

- The hot chamber at the top of the thermal shock chamber (TSA) has been changed to a high temperature and humidity chamber that can control humidity, thereby enabling dew cycle tests. With this new feature, it is possible to start a dew condensation cycle test right offer the completion of thermal cyde test, which is not possible with conventional thermal shock chamber.

- Conventional thermal cycle testing also available

- Simply operate a switch to selecting either thermal cycle or dew condensation cycle testing.

- Features similar to a simple humidity cycle chamber

-

- Excellent dew condensation.

- Prevention of water droplets falling from the ceiling by the control of the temperature on test area walls surface.

- Control of the dew condensation time and distribution by air circulation control device.

- You can set dry process through the controller for dew cycle test

- The dry process can now be set through the controller, which makes it easy for you to carry out bias and non-bias tests both in dew condensation and dry operation, which is essential for automotive parts.

- N-instrumentation equipped with a color LCD touch panel

- Wide 9-inch screen with LED backlight is clearer and provides faster display speed.

- Quick access button

- The star mark (★) on the right top corner of the controller can be set to have instant access to any page you often need, either registered test program start, on else.

- Output temperature data

- Sampling data (set values and reading values) is saved in internal memory at the rate of sampling frequency you set.

- Enhanced test halt preset function [patent 5456600]

- It is now possible to program tests to halt after cycle or exposure completion. Six cycle counters are also built-in to the instrumentation so a test halt preset can be programmed for each counter. The function can be used to multiple ends such as removing specimens to the chamber.

- Support daily inspection

- You can monitor system status such as refrigerator pressure and cooling water temperature on instrumentation screen and connected PC, which would support equipment management such as daily inspection.

- Overshoot and undershoot reduction

- Three-step input is available to reduce the overshoot and undershoot that occurs when reaching the set temperature.

- Register up to 40 test program patterns

- The memory increased by fourfold.

- Variety of time signal operation during dew condensation test

- The new controller allows you to set the drying process, as well as the time signal, etc., which was not possible in the previous models. With this new features, it enables you to carry out bias and non-bias tests both in dew condensation and dry operation.

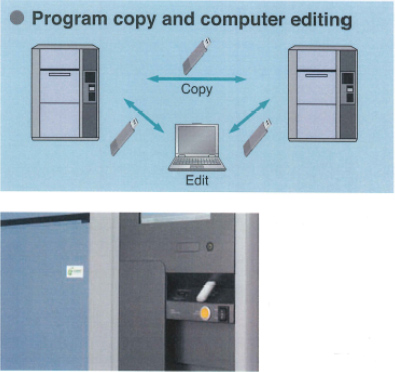

- Copy of test program patterns

- Transfer test programs between chambers without the need of a PC, via USB stick.

※The USB memory is not included. - Trend graph output on USB memory

- Trend graphs can be displayed on the web application or downloaded on a USB memory. It is also possible to continuously register data on the USB memory if numerous data records are needed.

- Chamber construction

- Main specifications

-

Model TSA-103D-W TSA-203D-W Power supply 200 V AC, 3 ohm, 3W, 50/60 Hz (Can support any power supply voltage as an option) Method Two-zone and three-zone using damper switching Performance*1 Test area*2 High-temp. exposure range - Thermal cycle test +70°C to +150°C

- Dew cycle test -10°C to +100°C

Low-temp. exposure range - Thermal cycle test -70°C to +10°C

- Dew cycle test -40°C to +10°C

Temperature fluctuation width ±1°C Humidity fluctuation width ±5% rh High temperature and humidity chamber

(single unit performance)Max pre-heat setting temperature +150°C Humidity range 40 to 95%rh (For dew cycle test) Temperature heat-up time Within 30 minutes from -10°C to +100°C Temperature pull-down time Within 60 minutes from +20°C to -10°C Low temperature chamber

(single unit performance)Min pre-heat setting temperature -75°C Temperature heat-up time Within 30 minutes from -75°C to +10°C Temperature pull-down time Within 60 minutes from ambient temperature to -75°C Temperature recovery performance*3 Thermal cycle test Recovery conditions - Three-zone

- Low temperature exposure: -65°C (30 minutes)

- Ambient-temperature exposure: ambient temperature (10 minutes)

- High temperature exposure: +150°C (30 minutes)

- Power supply voltage: rated voltage

- Sensor position: upstream

- Specimen: plastic mold IC 5kg

- Specimen: plastic mold IC 10kg

Recovery time High temperature recovery: within 10 minutes

(Ambient temperature→ +150°C)

Low temperature recovery: within 10 minutes

(Ambient temperature→ -65°C)High temperature recovery: within 16 minutes

(Ambient temperature→ +150°C)

Low temperature recovery: within 16 minutes

(Ambient temperature→ -65°C)Dew cycle test 1 Recovery conditions - Two-zone

- Low temperature exposure: +5°C (20 minutes)

- High temperature and humidity exposure operation : +25°C 90% (20 minutes)

- Power supply voltage: rated voltage

- Sensor position: upstream

- Specimen: print substrate 2 kg

- Specimen: print substrate 5 kg

Recovery time*4 High temperature recovery: within 20 seconds

(+5°C→+25°C 90%)

Low temperature recovery: within 3 minutes

(+25°C 90%rh→+5°C)High temperature recovery: within 20 seconds

(+5°C→+25°C 90%)

Low temperature recovery: within 5 minutes

(+25°C 90%rh→+5°C)Dew cycle test 2 Recovery conditions*5 - Two-zone

- Low temperature exposure: -30°C (60 minutes)

- High temperature and humidity exposure operation: +25°C 95% (60 minutes)

- *Pre-heating temperature 25°C 95%

- Power supply voltage: rated voltage

- Sensor position: upstream

- Specimen: no specimen

Recovery time*4 - High temperature and humidity recovery: within 5 minutes (-30°C→+25°C 95%)

- Low temperature and humidity recovery: within 5 minutes (+25°C 95%rh→-30°C)

Specimen basket load capacity 5kg (Equally distributed load) Test area dimensions W650×H460×D370mm W650×H460×D670mm Outside dimensions W1670×H1900×D1570mm

(excluding protrusions)W1670×H1900×D1870mm

(excluding protrusions)Weight Approx. 1,300 kg Approx. 1,550 kg - *1 With an ambient temperature of +23°C.

- *2 There are conditions for operation performance of a dew cycle test. Please contact us for more information.

- *3 With an ambient temperature of +23°C and a cooling water temperature of +25°C.

- *4 Performance of temperature only

- *5 Defrosting is required once using cycle defrosting every 12 cycles (may vary by ambient temperature).

- * The model is for operational purposes and may be changed after order. Thank you for your understanding.

- Actual application examples

-

· Dew condensation test Specimen: Automotive headlight, in-vehicle instruments · In-vehicle PCUs Heat generation of specimen 600 W · +5°C ⇔ +25°C/90%rh Test area recovery time High temperature recovery 20 sec

/Low temperature recovery 5 minExposure time 20 min Specimen:

Circuit mounted board* For more details including the support status of other testing standards, compatibility with system devices, and standards for automotive components such as JASO D014, please contact our sales representatives.

* For information on the ion migration evaluation system (AMI) and compatibility with various devices, please contact our sales representatives.

Recommended products for customers viewing this product

- Electro-chemical Migration Evaluation System

- Air to Air Thermal Shock Chamber

- Large Capacity Liquid to Liquid Thermal Shock Chamber

- Thermal Shock Chamber 300°C Specification

- Large Capacity Thermal Shock Chamber 603EL (600L)

- Highly Accelerated Air to Air Thermal Shock Chamber (HAATS)

- High-rate Thermal Cycle Chamber