Air to Air

Thermal Shock Chambers

TSA series

UN ECE Support for global standard tests including UN ECE R100-02.Part II and UN38.3 (T2)

Because these are stationary specimen systems in which the test area does not move, there is no vibration stress (on the specimen) caused by movement, ensuring more accurate test results.

- Test category (cell tests)

-

- Thermal cycle (thermal shock) test

- Test category (module and pack tests)

-

- Thermal cycle (thermal shock) test

- Supported test standards

-

- UN ECE R100-02.PartⅡ

- UN38.3

- JISC8712

- UL1642

- Electrical Appliance and Material Safety Act

- ISO12405-1

- ISO12405-2

- IEC62660-2

Features

Original structure that prevents frost from forming (option: defrost-free model)

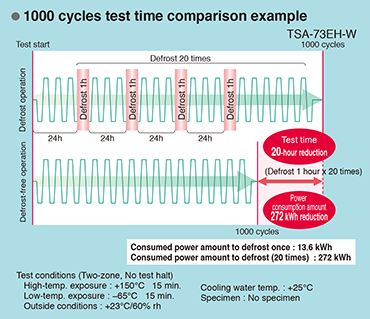

Defrosting can be performed without interrupting the test, allowing continuous operation of up to 500 hours. With 15-minute exposure test conditions, it is possible to conduct 1,000 continuous cycles without interruption, making it possible to reduce the time and power required for defrosting during cycle operation.

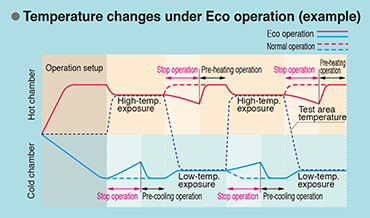

Automatic setting of pre-cooling or pre-heating times for energy-saving eco operation functions

The required amount of heat is continually measured, and the operating time with the shortest pre-cooling or pre-heating time is calculated automatically, shortening the temperature recovery time. This allows testing that achieves energy savings as well as reproducibility and reliability.

Further energy savings are achieved by the refrigerator parallel control system.

In order to reduce power consumption, a parallel control system is provided with 2 compact refrigerators installed in parallel on the low- and high-stage side of the refrigeration circuit. This optimizes refrigeration capacity while also delivering further energy savings.

Wide range of optional safety measures

A fire extinguishing system, gas detector, and a wide range of other safety measures are available.

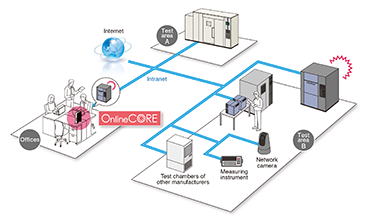

Remote monitoring and control

(via Ethernet connection)

The chambers are equipped with unique web applications that enable chamber status to be confirmed and operated from a web browser (PC or tablet). It is also possible to start operation with a PC or other device from a remote location. In addition, details of alarms that have been triggered can be sent to pre-registered PC or mobile phone e-mail addresses.

Specifications

| Model | Temperature range | Inside dimensions |

|---|---|---|

| TSA-43EL | High temp. exposure: Ambient temp. +50 to +200°C Low temp. exposure: –65 to 0°C |

W240 × H460 × D370mm |

| TSA-73EL | W410 × H460 × D370mm | |

| TSA-103EL | W650 × H460 × D370mm | |

| TSA-203EL | W650 × H460 × D670mm | |

| TSA-303EL | W970 × H460 × D670mm | |

| TSA-73ES | High temp. exposure: Ambient temp. +60 to +200°C Low temp. exposure: –70 to 0°C |

W410 × H460 × D370mm |

| TSA-103ES | W650 × H460 × D370mm | |

| TSA-203ES | W650 × H460 × D670mm | |

| TSA-73EH | W410 × H460 × D370mm |

Larger capacity type

Larger capacity Thermal Shock Chamber

A wide range of sizes are available including 1,650 L and 3,300 L. This makes possible thermal shock evaluations of large-size battery packs and other large products.