Nail penetration, crush, and

external short circuit test systems

ADST series

The final word in cell safety test systems, with one system able to perform 4 different tests

A lineup of large-size safety test systems for a wide range of battery packs is also available

Modules have been created that contain the test functions necessary for cell nail penetration, compression, eternal short circuit, and overcharge and forced discharge tests. This makes it possible to construct a system composed of a single safety test temperature chamber equipped with the necessary combination of functions.

- Test category (cell tests)

-

- External short circuit test

- Overcharge and forced discharge test

- Nail penetration test

- Crush test

- Test category (module and pack tests)

-

- External short circuit test

- Overcharge and forced discharge test

- Nail penetration test

- Crush test

- Supported test standards

-

- UN ECE R100-02.PartⅡ

- UN38.3

- JISC8712

- JISC8714

- UL1642

- Electrical Appliance and Material Safety Act

- UL2054

- ISO12405-1

- ISO12405-2

- ISO12405-3

- IEC62660-1

- IEC62660-2

- IEC62660-3

- UL2580

- SAE J2464

- GB38031-2020

Features

Support for a variety of test standards by changing the holder jig!

There are a variety of test standard requirements for crush tests, and the test conditions span a large range.

Crush holder jigs utilize a chuck structure for changeable jigs, allowing the system to be used for many different tests.

At the nail penetration test, because the nail shape and material will affect the test results, tests can be performed using a variety of different nail types.

A resistance adjustment function to support a variety of test standards

There are a variety of test standard requirements for external short circuit tests, and the test conditions span a large range. By providing a resistance adjustment function, it is possible to adjust the short circuit resistance according to the test conditions.

The resistance fine adjustment function can also be used to create a reproducible test environment for changes in circuit resistance that occur as a result of aging.

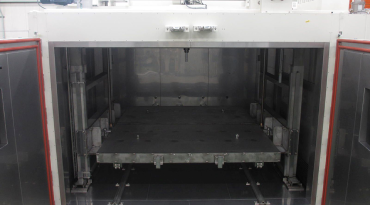

Nail penetration tests of battery packs are also supported.

Nail penetration tests of large-size battery packs are also possible.

The motorized elevating specimen stage makes it possible to conduct nail penetration tests in the vertical direction.

The structure that is integrated with the temperature chamber allows tests to be performed in actual temperature environments.

Specimen stage dimensions: 2000×2000 mm

Temperature range: -40°C to +80°C

Crush tests of battery packs are also supported.

Crush tests of large-size battery packs are also possible.

These are lateral-type crush test systems that simulate the compression directions that can occur with an on-board battery pack.

Changing the holding jig makes it possible to also conduct nail penetration tests in the horizontal direction.

Test area dimensions: 2000×2000 mm

Load: Maximum 1000 kN, continuous 100 kN

Speed: 0.01 to 1.5 mm/sec

External short circuit tests of battery packs are also supported.

External short circuit tests of large-size battery packs are also possible.

Standard tests and tests in actual temperature environments can be conducted for a wide range of on-board battery packs.

Applicable battery voltages: Maximum 500 V

Short circuit current: Maximum 24 kA

Short circuit resistance: 5 mΩ or less

Temperature range: -40°C to +80°C

Specifications (Example)

Nail penetration & crush test system

| Category | Item | Specifications(example) | Remarks/notes |

|---|---|---|---|

| Load | Control range | 0.5~20kN | Guaranteed value at -20 to +60°C in test area (average control load) |

| Accuracy | ±4%FS | ||

| Minimum setting unit | 0.001kN | ||

| Speed | Control range | 0.1~150mm/sec | |

| Accuracy | ±0.5mm/sec | Average velocity after reaching the velocity setpoint, except for acceleration and deceleration. The velocity setpoint may not be reached if it is larger than the stroke setpoint. |

|

| Minimum setting unit | 0.001mm/sec | ||

| Stroke | Control range | 20~200mm | |

| Stop position accuracy | ±0.1mm | Values are guaranteed for no-load condition, at internal chamber temperature 25±10°C | |

| Minimum setting unit | 0.001mm |

External short circuit test system for cells and modules

| Item | Specifications(example) | Remarks/notes |

|---|---|---|

| Applicable battery voltage | 0 ~ 50V | |

| Applicable short circuit load | DC 50 V, 2000 A (5 seconds) | |

| Short circuiting circuit resistance | 30m Ω /80m Ω | • Selected resistance can be changed from the external short circuit test unit. • Resistance value at end of provided load cable |

External short circuit test system for pack

| Item | Specifications(example) | Remarks/notes |

|---|---|---|

| Applicable battery voltage Rated electric current when energized |

0 to 750 V 500 A / 2 hours |

|

| Overload electric current when energized | 16,16,000 A / 0.1 second ↓ 12,500 A / 0.4 seconds ↓ 2,500 A / 10 seconds ↓ 800 A / 60 seconds |

|

| Short circuiting circuit resistance | 下記3 The resistance value can be changed to the following 3 levels. | • The resistance value can be selected with the shorting bar included with the external short circuit load system. • The resistance can be adjusted using the adjustment resistor. (0 to 7 mΩ in 1 mΩ increments) • The resistance value is the value at either end of the battery connection output terminal board in the external short circuit load system. |

Product (Example)

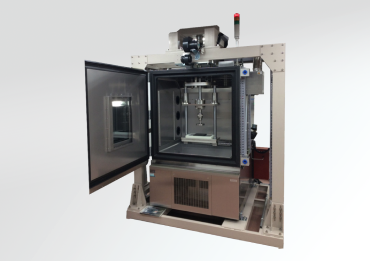

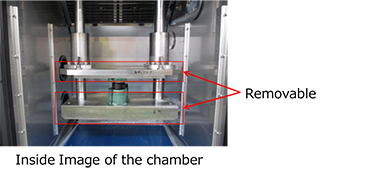

Nail penetration & crush test system for small cells

Because the crush holding jig can be changed, a variety of test standards can be applied. Because the system can also be changed to mount nails of a variety of materials and sizes, nail penetration tests are also possible.

Pressure: 0.5 to 20 kN

Speed: 0.1 to 150 mm/sec

Stroke: 20 to 200 mm

The temperature chamber is equipped with pressure release vents to release pressure in the chamber when a battery event occurs, a CO2 fire extinguisher, and viewing window equipped with a web camera for observing inside the test area.