Cell charge/

discharge test systems

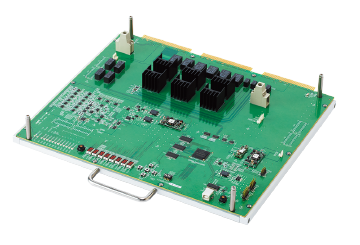

ADBT series

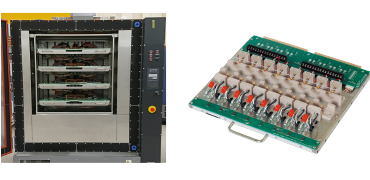

Structure which integrates a charge/discharge system and temperature chamber to support the future of secondary batteries

All-in-one systems combine the functions required for charge/discharge evaluations of secondary batteries in a single package.

We will propose the optimal single system that combines various types of charge/discharge power supplies, temperature chambers, battery installation jigs (battery holders), safety functions, and measurement functions selected according to the testing purpose.

- Test category (cell tests)

-

- Charge/discharge test

Features

All-in-one charge/discharge test systems

Combinations of 4 types of temperature chambers (three-chamber type, single-chamber type, wide single-chamber type, or individual temperature control type) and various power supplies are possible in order to match the customer’s battery size, installation quantity, and test contents.

- Integrated structure for space savings

- Optimizing the air conditioning structure and the use of a special battery installation jig (battery mounting board) minimizes temperature differences between batteries.

- The use of battery mounting boards that can be inserted and removed allows safe battery installation and removal disconnected from the charge/discharge power supply.

- A parallel function on the 10 A and 50 A power supplies allow tests at higher currents.

Support for on-board cells with larger sizes and higher outputs

Based on a 5 V / 100 A power supply, charge/discharge tests up to a maximum of 5 V / 1600 A are possible.

The high precision and fast response allow higher accuracy evaluations.

| Typical specification item | Specification for on-board products |

|---|---|

| Current/voltage range | 5V/100A 〜 1600A |

| Current/voltage accuracy | 0.03% of F.S. |

| Charge/discharge response performance※ 1 | 5 ms or less ※1 |

| High-speed sampling | Minimum 10 ms |

※ 1:Time from less than 90% of the pre-change set current value to 90% or more of the post-change set current value

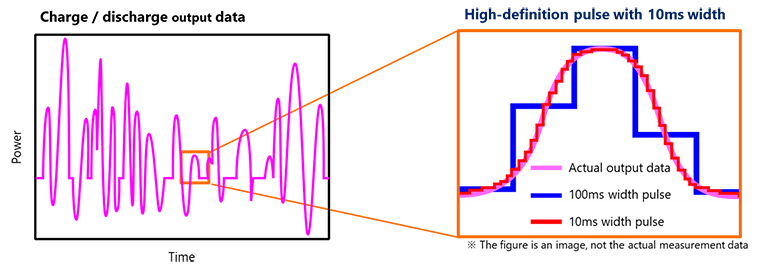

Support for pulse tests that simulate actual vehicle driving patterns

High-speed switching between charging and discharging within 5 ms allows high precision reproduction of actual vehicle driving patterns.

- Constant current and rated power discharge pulse control with a minimum pulse width of 10 ms

- Seamless output up to maximum 240,000 pulses

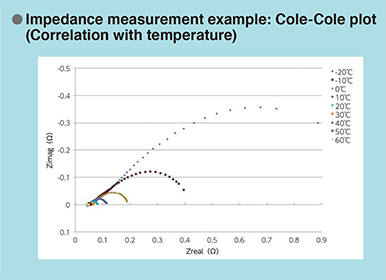

Impedance measurement function (optional)

Adding an impedance measuring instrument allows seamless transitions between charge/discharge testing and impedance measurement.

- Previously, the charge/discharge system and impedance measurement system were separate systems. Integrating them eliminates the need to move the batteries between the charge/discharge test and impedance measurement systems. This allows tests under constant contact and wiring conditions from test start to finish, enabling evaluations with little outside disruption.

- By connecting the impedance measuring instrument and original ESPEC scanner unit, it is possible to switch between multiple channels, allowing measurement with little error between channels.

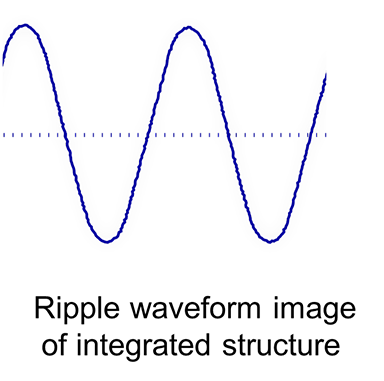

Ripple superposition function (optional)

This is capable of evaluating the performance deterioration caused by high-frequency ripple current in the inverter of an on-board battery motor. The test can be performed by superimposing AC current on the charge/discharge current.

- The integrated structure reduces the length of the cable between the battery and the charge/discharge power supply. This allows superimposition of an AC waveform with little noise.

Calibration that can be performed by the customer (optional)

The charge/discharge power supply that requires high accuracy must be calibrated periodically. However because the charge/discharge test periods vary in length from a week to several months, it is difficult to coordinate the calibration timing. The use of an automatic calibration board allows the customer to easily perform calibration and accuracy adjustment.

It is also possible to provide rapid calibration in case there is a request for calibration when the test request is received from the customer.

Specifications

Combinations of a wide range of temperature chambers and charge/discharge power supplies

A wide lineup covering small to large-size batteries allows the customers to select the optimal charge/discharge system for their batteries.

| Type | Three-chamber type | Single-chamber type | Wide single-chamber type | Four area-chamber type | ||

|---|---|---|---|---|---|---|

|  |  |  |

|||

| Interior dimensions(mm) | W510 H400 × 3chamber D400 |

W640 H850 D544 |

W890 H850 D544 |

W1130 H980 D525 |

||

| Outside dimensions(mm) | W950 H2022 D1300 |

W1250 H1875 D1560 |

W1750 H2030 D1690 |

W1590 H2410 D1954 |

||

| Standard | ADBT-5-1 | 5V、1A | 72ch (24ch/chamber) |

72ch | ー | ー |

| ADBT-5-10 | 5V、10A | 72ch(24h/chamber) | 72ch | ー | ー | |

| ADBT-5-50 | 5V、50A | 24ch(8h/chamber) | 24ch | ー | ー | |

| High-speed High-current |

ADBT-6-400 | 6V、400A | 3ch(1h/chamber) | contact us | 4ch | 4ch |

| ADBT-6-600 | 6V、600A | 3ch(1h/chamber) | contact us | contact us | 4ch | |

| ADBT-6-100 〜 ADBT-6-1600 |

6V、100A 〜 6V、1600A |

Please contact ESPEC or your dealer regarding combination patterns with other power supplies and temperature chambers. | ||||

Primary temperature chamber and charge/discharge power supply specifications

| Model | Standard | High-speed High-current |

|||

|---|---|---|---|---|---|

| ADBT-5-1 | ADBT-5-10 | ADBT-5-50 | ADBT-6-400 | ||

| Test area | Temperature range | - 40°C~+ 100°C | |||

| Temperature uniformity | ± 1.5°C | ||||

| Output voltage | Setting ranges | 0 ~ 5000mV(5V) | 0 ~ 6000mV(6V) | ||

| Output accuracy | ± 0.1% of F.S | ± 0.03% of F.S | |||

| Output current | Setting ranges | 0〜1mA 0〜10mA 0〜100mA 0〜1A |

0〜100mA 0〜1A 0〜10A |

0〜500mA 0〜5A 0〜50A |

0〜40A 0~400A |

| Output accuracy | ± 0.1% of F.S | ± 0.03% of F.S | |||

| Charge/discharge switching | 100 msec or less | 5 msec or less | |||

| Output power | Setting ranges | 0〜5W | 0〜50W | 0〜250W | 0〜2000W |

| Output accuracy | ± 0.2% of F.S | ± 0.08% of F.S | |||

| Parallel function | 2 parallel | ー | 16A | 80A | ー |

| 4 parallel | 32A | 160A | |||

| Measurement points | Current/voltage | Current 1 point/channel, voltage (specimen edge) 1 point/channel | |||

| Temperature | 1 point/channel | 2 point/channel | 1 point/channel | ||

| Pulse mode | Pulse width(Min.) | 1sec | 10sec | ||

| Number of pulse | 5000 pulse | 6000 pulse× 2 | |||

Recommended Options Package

Package of functions required for evaluations of on-board cells

- ①Support for high-capacity EV batteries and high-output HEV batteries

→ 6 V / 600 A × 4 ch - ②Temperature tests with minimal temperature variation between batteries

→ Uniquely designed charge/discharge test temperature chambers equipped with individual air conditioning functions - ③Charge/discharge simulation tests using actual vehicle driving patterns

→ Minimum 10 ms width pulse output function - ④Automatic measurement of battery internal resistance changes

→ Embedded impedance measurement function - ⑤Evaluations of the effects from inverter high-frequency ripple

→ Low noise ripple superposition function

Package of functions required for evaluations of small cells

- ①A single system that can perform evaluations at 3 temperature levels (low temperature, ambient temperature, high temperature)

→ Three-chamber type temperature chamber - ②Support for low-rate to high-rate testing of all kinds of cells including cylindrical, square, and laminated

→ Selection of 5 V / 10 A or 5 V / 50 A power supply and parallel function - ③Automatic measurement of battery internal resistance changes

→ Embedded impedance measurement function - ④Safe testing environment

→ CO2 fire extinguisher, pressure release vent, screw-in lock