Energy Device Environmental Test Center

Laboratory Testing Services

From charge/discharge testing to safety testing, model certification testing, and limit testing, we will propose the optimal test method according to the customer’s development status.

- 可能な試験項目

-

- Vibration test

- Fire resistance test

- Overheating test

- Salt water immersion test

- Thermal shock test

- External short circuit test

- Reduced pressure (altitude) test

- Nail penetration test

- Impact test

- Overcharge test

- Drop test

- Cell charge/discharge test

- Crush test

- Over-discharge test

- Thermal propagation test

- Module charge/discharge test

- Supported test standards

-

- UN ECE R100 Rev.3 PartⅡ

- UN38.3

- GB/T 31467.3

Supported international test standards

UN recommended transport test UN38.3

Following the lithium metal battery fire that occurred at a U.S. airport in 2003, transport regulations for lithium-ion batteries (LiB) were formulated in the United Nations “Recommendations on the transport of dangerous goods: manual of tests and criteria,” which prescribes safety standards for international transport of a wide range of dangerous goods.

The lithium-ion battery test methods and standards are prescribed in subsection 38.3 of this manual, and international transport of lithium-ion batteries (by sea, air, or rail) requires that these tests be passed.

United Nations regulation UN ECE R100 Rev.3 PartⅡ

Electric vehicles and similar products that are certified in and after July 2016 are required to conform to United Nations regulation UN ECE R100 Rev.3 PartⅡ. At ESPEC test laboratories, we not only have test equipment that can perform tests for all 9 items required by this UN regulation, but also have a system which can meet a broad range of needs including limit testing during the development phase, and support for various measurements.

Energy Device Environmental Test Center

Certification testing

In addition to equipment that can perform tests for automobile UN ECE R100 Rev.3 PartⅡ. Part II and the UN recommendations on the transport of dangerous goods in UN38.3, in the quality area we have also acquired ISO/IEC 17025 certification for both standards and have a complete system for supporting the acquisition of certification by the customers. In addition to automobiles, we have acquired JISC8715-2 standard certification, and provide support for battery evaluations with test contents that are specific to each field or industry. Since the testing center opened in 2015, we have carried out large quantities of certification tests, and can apply this experience and record of success to helping our customers acquire certification.

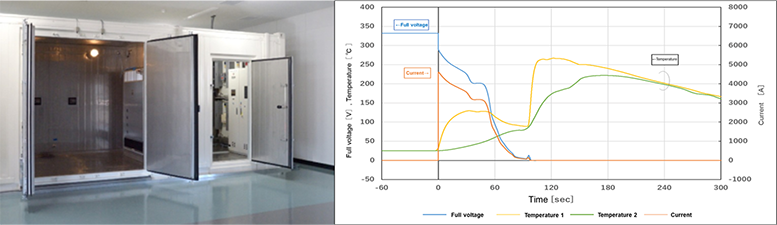

Charge/discharge testing

[Cell charge/discharge testing]

The structure which integrates the charge/discharge system and temperature chamber allows cable-free operation inside the chamber. This reduces the electrical power loss caused by the cable and improves electrical response, allowing high-accuracy, high-quality tests. Evaluation tests including constant current and constant voltage discharge, discharge temperature characteristics, and discharge rate characteristics are possible.

[Module and pack charge/discharge testing]

These systems can also be used for SOC adjustment at the safety tests for lithium-ion batteries required by the UN recommendations on the transport of dangerous goods or UN regulation UN ECE-R100. Voltage and current can be flexibly controlled by the system combination. Feel free to consult with us.

Advanced testing

One of the most difficult safety tests for lithium-ion batteries is the fire resistance test. These tests, which require that an amount of fuel prescribed by the standard be ignited and that a special screen be used, involve numerous difficulties including jigs that can install the battery pack, the movement mechanism, smoke discharge equipment, and fire extinguishing equipment. Since our testing center first opened, ESPEC repeated a long process of trial and error in order to develop the methods that we currently use. Compared to outdoor tests, indoor tests are less susceptible to the effects of wind, and it is possible to create uniform test stress. As a result, it is possible to provide tests with a high level of reproducibility.

Disposal of batteries after testing

One issue faced in evaluations of lithium-ion batteries is the handling of batteries after testing is completed. Conditions inside the batteries are abnormal or unstable following the tests, and their relocation and dismantling are extremely difficult. When there are protective functions installed on the cell or module level, electrical discharge of the battery is difficult and in some cases physical destruction may be required. At ESPEC, our testing personnel have extensive knowledge of batteries, and render batteries safe for transport using methods that were developed based on experience and past success, in order to return specimens to the customer.

Example of Test

Introduction to the external short circuit test

Here we will introduce the external short circuit test that is prescribed in a variety of standards including UN ECE R100 Rev.3 PartⅡ and UN38.3. ESPEC external short circuit test systems are designed for short circuit current of large-size pack batteries. They feature maximum current of 24,000 A, short circuit resistance of 1 mΩ to 100 mΩ, a temperature sampling speed of 1 μsec, and a temperature range of -40 to +80°C. By applying a temperature load, it is possible to perform tests under conditions that are closer to the market environment.

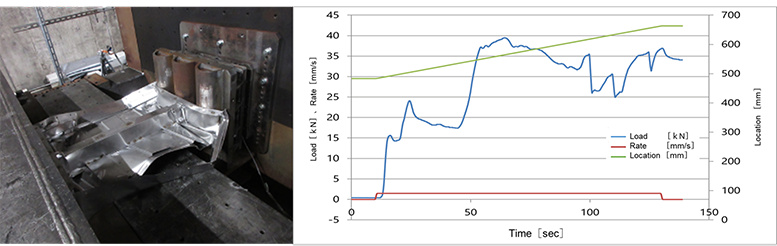

Introduction to the crush test

Here we will introduce the crush test that is an evaluation required for automobile battery packs. ESPEC crush test equipment is capable of applying a maximum load of 1,000 kN, far exceeding the 105 kN load required in UN ECE R100 Rev.3 PartⅡ.

Measurement items: Load, speed, displacement

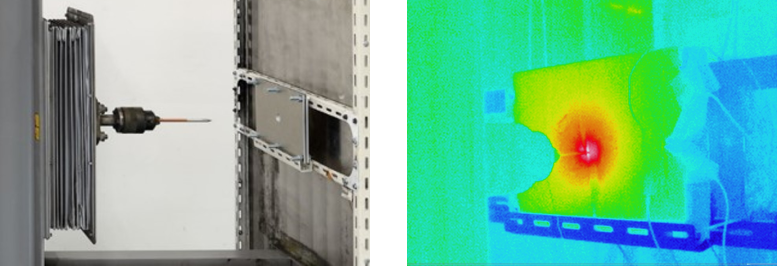

Introduction to the nail penetration test

The nail penetration test is a characteristic test performed in evaluations of lithium-ion battery cells and modules. The ESPEC nail penetration test systems are original systems that were developed by our company. They can achieve speed control of 1 to 100 mm/sec, and support a variety of test standards.

Measurement items: Load, speed, displacement, high-speed video

At-home Online Services

Real-time remote testing that can be observed from an office

ESPEC has constructed a system that allows customers to conduct environmental testing operations from home by remote instructions without an on-site presence.

● Monitoring of test progress using qualitative information (appearance degradation) and quantitative data, as well as test discussions involving multiple participants (such as other offices or end users), can be performed from home.

● Specimen installation at test start, setup, startup of the customer’s own systems, adjustment, monitoring of test data, and instructions for disassembly and packaging after the test can also be performed from home.