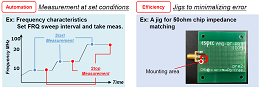

- In the 1 to 100 MHz frequency range, this system can automatically evaluate measurements of electrostatic capacity (C), reactance (L), impedance (Z), and Q value.

- Saves labor in tests by simultaneously measuring multiple channels.

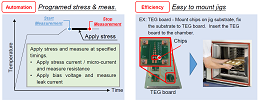

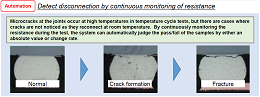

- Can conduct automatic measurements at preset conditions by working in conjunction with the temperature chamber.

| Model | AMQ-RF |

|---|---|

| Number of measurement channels | 36 channels * Expandable |

| Measurement range | Frequency: 1M~100MHz L:1n~100μH Q:0.1~100 Z:100mΩ~1kΩ C:1pF~100nF |