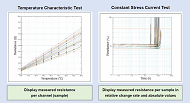

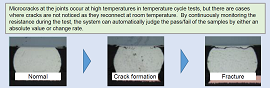

- Performs evaluations by accelerating electrical conduction failures due to thermal warping with the application of a constant current under high temperature and measuring the change in resistance.

- Saves labor by automatically displaying graphs using the analysis software.

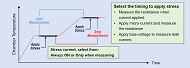

- Applies stress current to specimens by working in conjunction with the temperature chamber and measures resistance.

- Saves labor in tests by simultaneously measuring a maximum of 240 channels.

| Model | AEM |

|---|---|

| Number of measurement channels | maximum of 240 channels |

| Stress current source output range |

+DC0.1~200mA * Contact ESPEC regarding the current range. |

| Supported ESPEC temperature chambers |

AEM dedicated high-accuracy temperature chamber (Temperature range +65 to +350°C) |